Professional Equipment Manufacturer

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

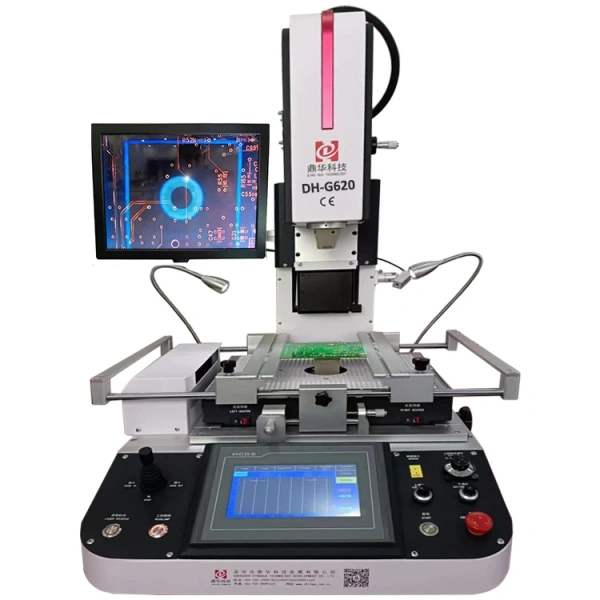

Essential Insights on Manual BGA Rework Stations for Industrial Equipment Repair

2025-04-30

One of the primary functions of a Manual BGA rework station is to facilitate the precise removal and replacement of BGA components. Unlike surface mount technology (SMT), BGAs require specialized techniques due to their unique soldering arrangements. Manual rework stations often come equipped with hot air tools, soldering iron tips, and sometimes, even microscope features to aid in the alignment and inspection of components. This precision is critical in ensuring that the reassembly is successful and that there are no solder bridges or cold joints that could compromise the circuit's functionality.

In addition to their removal and replacement capabilities, Manual BGA rework stations offer several benefits for industrial technicians. Firstly, they allow for greater control over the rework process. Operators can adjust temperature settings, airflow, and timing to suit the specific needs of the components being worked on. This level of customization helps reduce the risk of damage to the components or nearby PCB traces during the rework process, making it a safer option.

Moreover, the ability to perform repairs on-site reduces downtime significantly. Instead of replacing entire boards, technicians can efficiently replace only the defective components, which can result in cost savings and quicker turnaround times. This is especially advantageous in industries where equipment uptime is critical.

To maximize the effectiveness of a Manual BGA rework station, technicians should adhere to best practices. Ensuring that the workspace is clean and organized will help maintain focus and reduce errors. Additionally, using proper tools and techniques, such as preheating the PCB, can improve solder flow and adhesion. Regular maintenance of the rework station itself is also essential to ensure optimal performance and longevity.

In conclusion, a Manual BGA rework station is a cornerstone tool for professionals engaged in the repair and maintenance of industrial equipment. By understanding its functionalities and adhering to best practices, technicians can enhance their repair capabilities, ultimately leading to improved equipment performance and reliability. Investing in the right training and resources will further empower technicians to execute repairs with precision and confidence, making a significant impact on operational efficiency.

Keywords:

Related News

Essential Insights on Manual BGA Rework Stations for Industrial Equipment Repair

In the realm of industrial equipment repair, a Manual BGA (Ball Grid Array) rework station stands out as an invaluable tool for technicians and engineers. These stations are specifically designed for the rework and repair of BGA components on printed circuit boards (PCBs), a common requirement in various electronic devices and machinery. Understanding how to effectively utilize a Manual BGA rework

From Beginner to Pro: Mastering Your BGA Rework Station for Enhanced Industrial Equipment Repair

From Beginner to Pro: Getting Started with Your BGA Rework Station Table of Contents 1. Introduction to BGA Rework Stations 2. Understanding BGA Rework Technology 3. Essential Tools for Your BGA Rework Station 4. Setting Up Your BGA Rework Station 5. Key Techniques for Effective BGA Rework 6. Troubleshooting Tips for BGA Rework 7. Safety Precautions When Using a BGA Re

Nepcon China

Mastering BGA Rework Stations: Essential Insights for Industrial Equipment Maintenance

When it comes to maintaining and repairing industrial equipment, BGA (Ball Grid Array) rework stations have become indispensable tools. These stations are specifically designed for soldering, removing, and replacing BGA components on printed circuit boards (PCBs). Understanding how to effectively use a BGA rework station can greatly enhance the quality of your repairs and extend the lifespan of yo