Professional Equipment Manufacturer

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

DH-A2E Automatic BGA rework station

Categories:

Keywords:

Product introduction

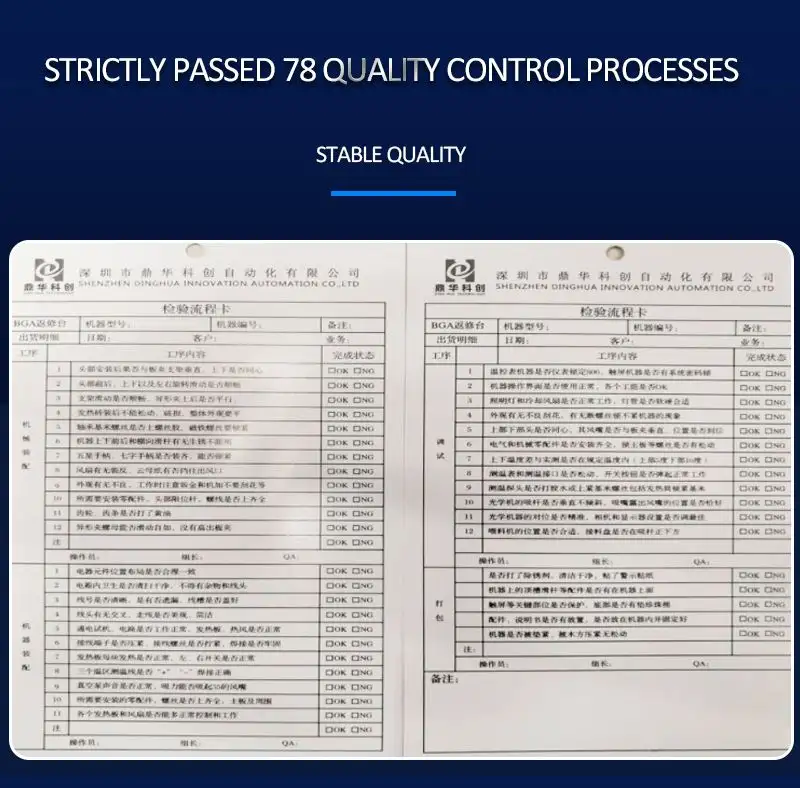

DH-A2E Automatic BGA rework station parameter

| Rated power | 4900W |

| Upper power | 1200W |

| Bottom power | 2nd :1200W; 3rd:2400W |

| Temperature accuracy | ±2 ℃ |

| External tempertures‘ ports | 1 pcs (optional) |

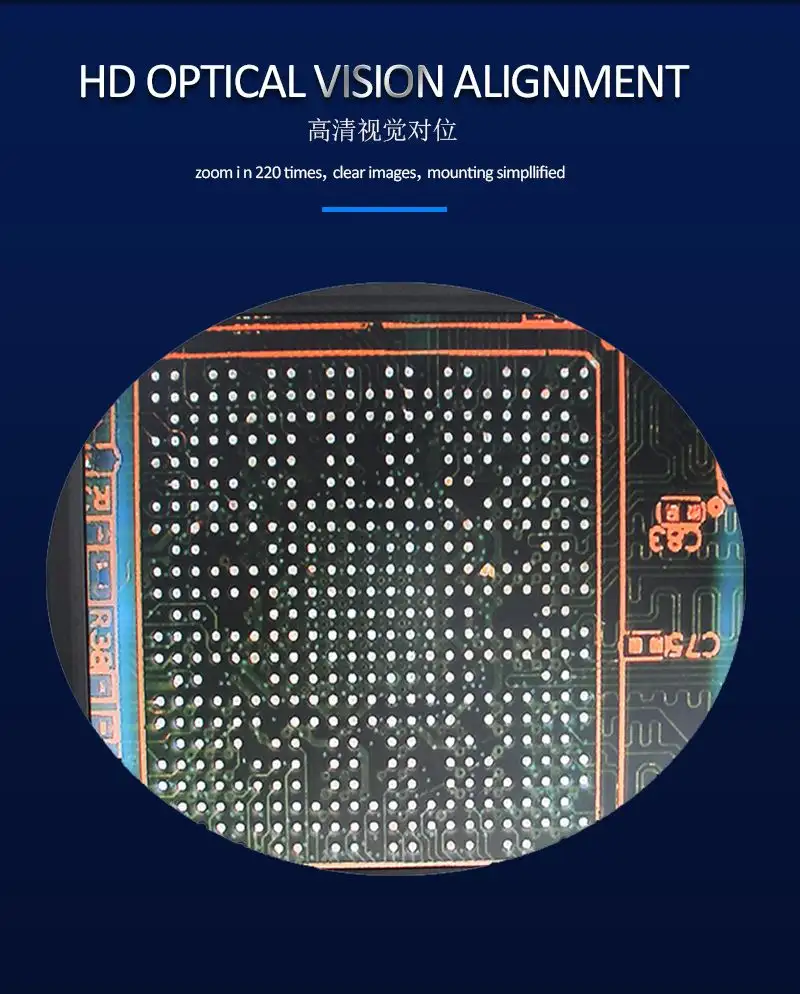

| Alignment accuracy | 0.01mm |

| Motherboard size | Max400*450mm Min 10*10mm |

| Chip spacing | 0.1mm |

| Chip-feeding | Automatic picking up and replacing |

| Mounting | Automatically mounting |

| Optical CCD | Automatically going out and back, and focus. |

| Dimension | L600mm*W700mm*H850mm |

| Net weight | 70kg |

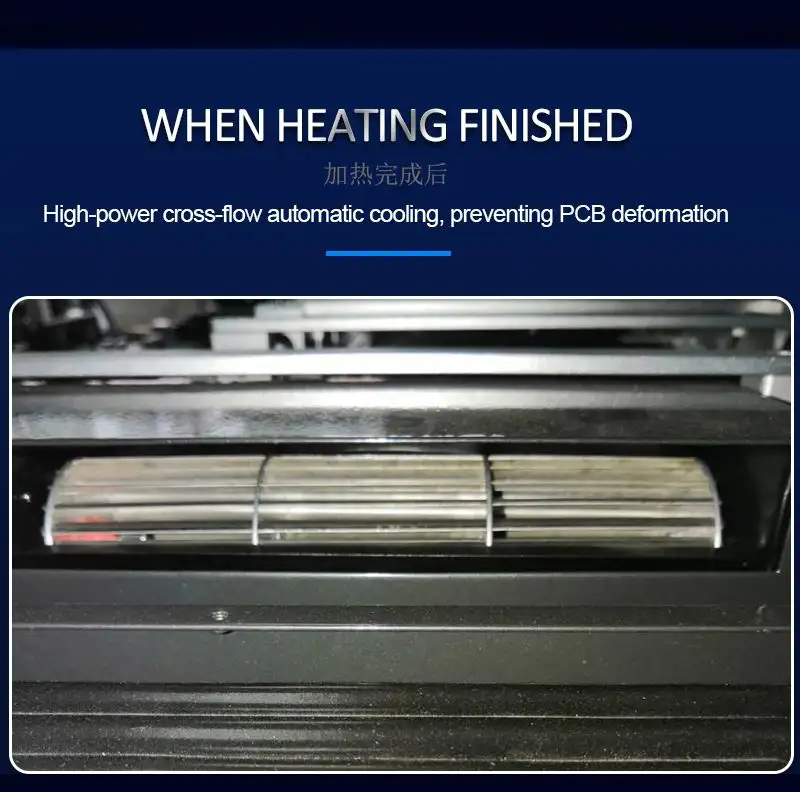

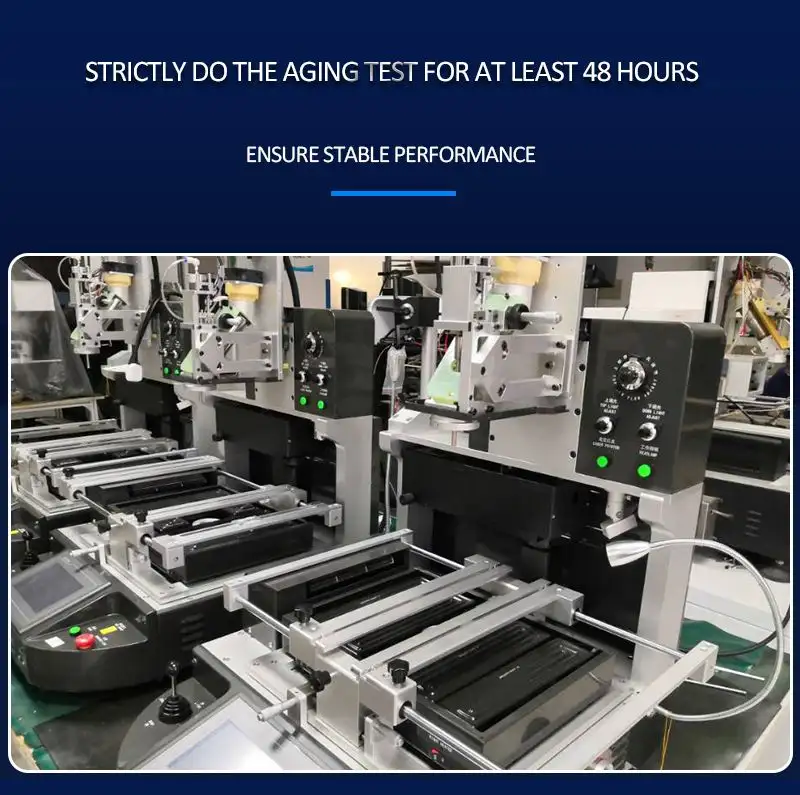

The Automatic BGArework station is a technological marvel that has significantly transformed the landscape of rework operations in various industries.

In the manufacturing world, rework is an essential but often complex and time - consuming process. It involves correcting defects or making modifications to products that do not meet the required quality standards during the initial production phase. The Automatic BGArework station has been designed to streamline this process, bringing in a high level of efficiency and precision.

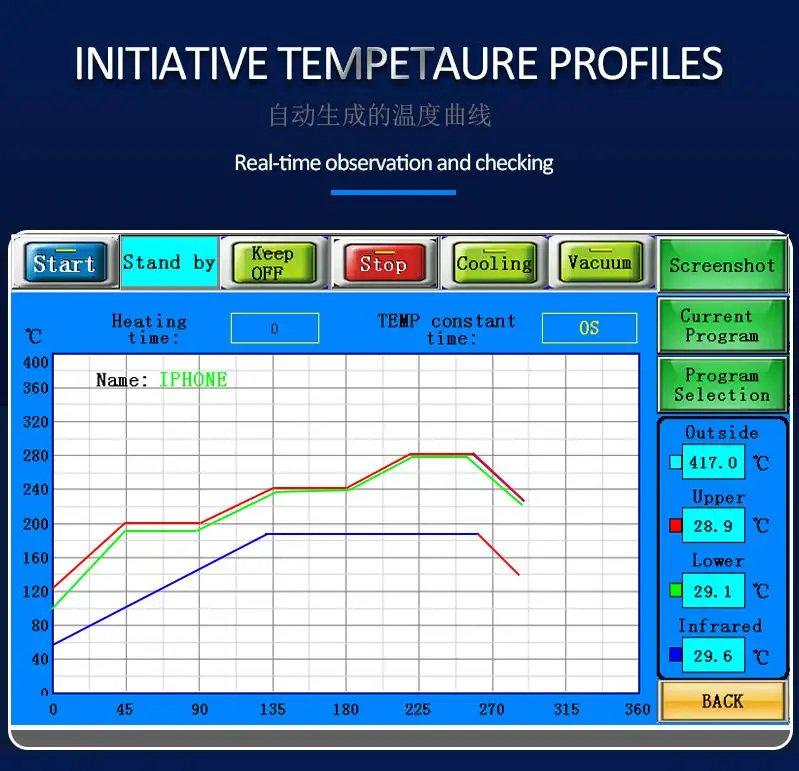

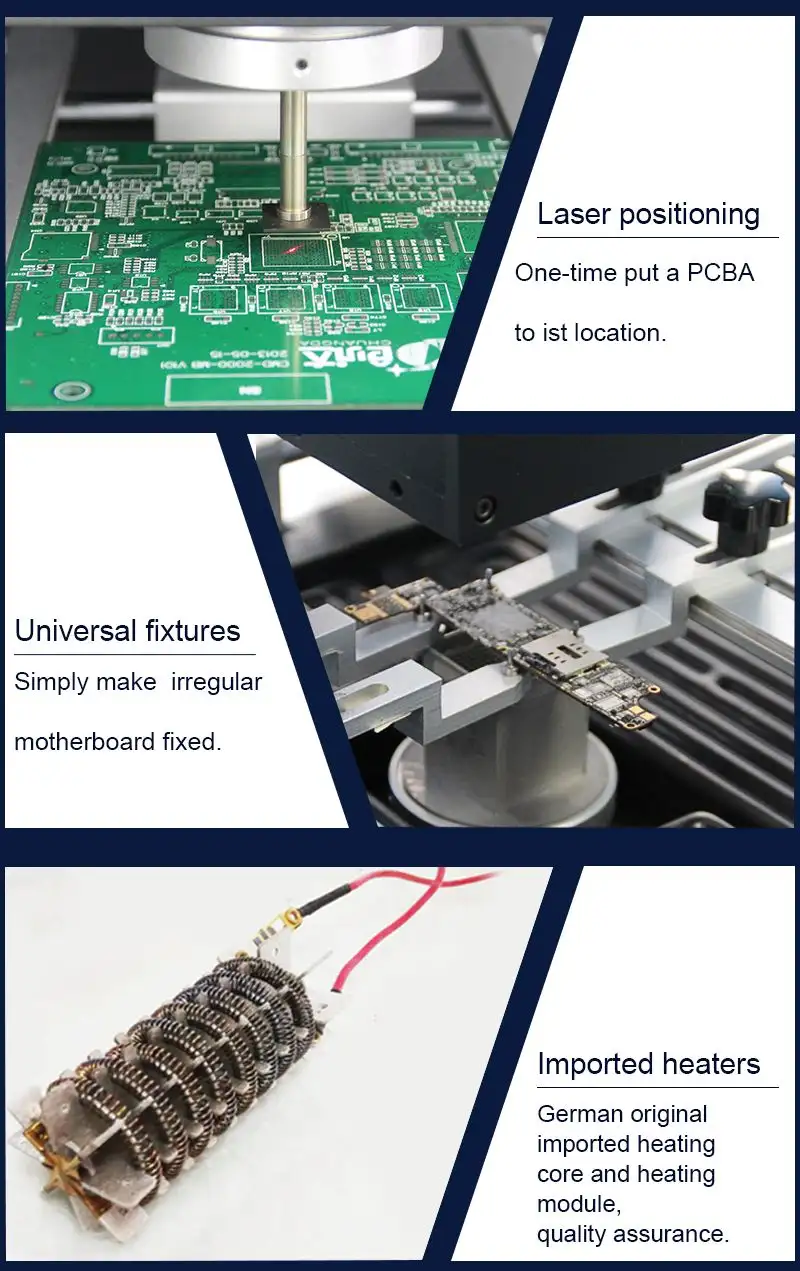

One of the key features of the Automatic BGArework station is its automation capabilities. Traditional rework processes often rely on manual labor, which is not only prone to human error but also time - intensive. With automation at the core of this workstation, it can perform a series of rework tasks with a high degree of consistency. For example, it can accurately identify the defective areas on a printed circuit board (PCB) or other components. Through advanced sensors and imaging technology, it can detect even the minutest of flaws that might be overlooked by the human eye.

The precision of the Automatic BGArework station is another remarkable aspect. Once the defective area is identified, the workstation can carry out the necessary rework actions with utmost accuracy. Whether it is soldering, desoldering, or replacing a component, the workstation can perform these tasks with a level of finesse that is difficult to achieve manually. This precision is crucial in industries where the quality and functionality of the end - product are of utmost importance, such as in the electronics and aerospace sectors.

FACTORY WORKSHOP

CUSTOMER TRANSACTION

Adhering to the business principle of mutual benefits, we have had a reliable reputation among our customers because of our professional services, quality products and competitive prices.

CUSTOMER TRANSACTION

We welcome customers at home and abroad to visit our factory to reach long-term cooperation and create success together.

FAQ

Can you make a proof for using automatic soldering station:

Yes, please send us your motherboards and components,we can even customize a jig/fixture which will hold your motherboard & components on Machine’s table for soldering.

What is a BGA reworkstation?

Dinghua BGA rework stations, featured with 3 independent heating-area, PID controlling temperatures, real-time curves displaying on touchscreen, is a station used for various chips and a few components desoldering or soldering.

Are you a manufacturer or a trading company?

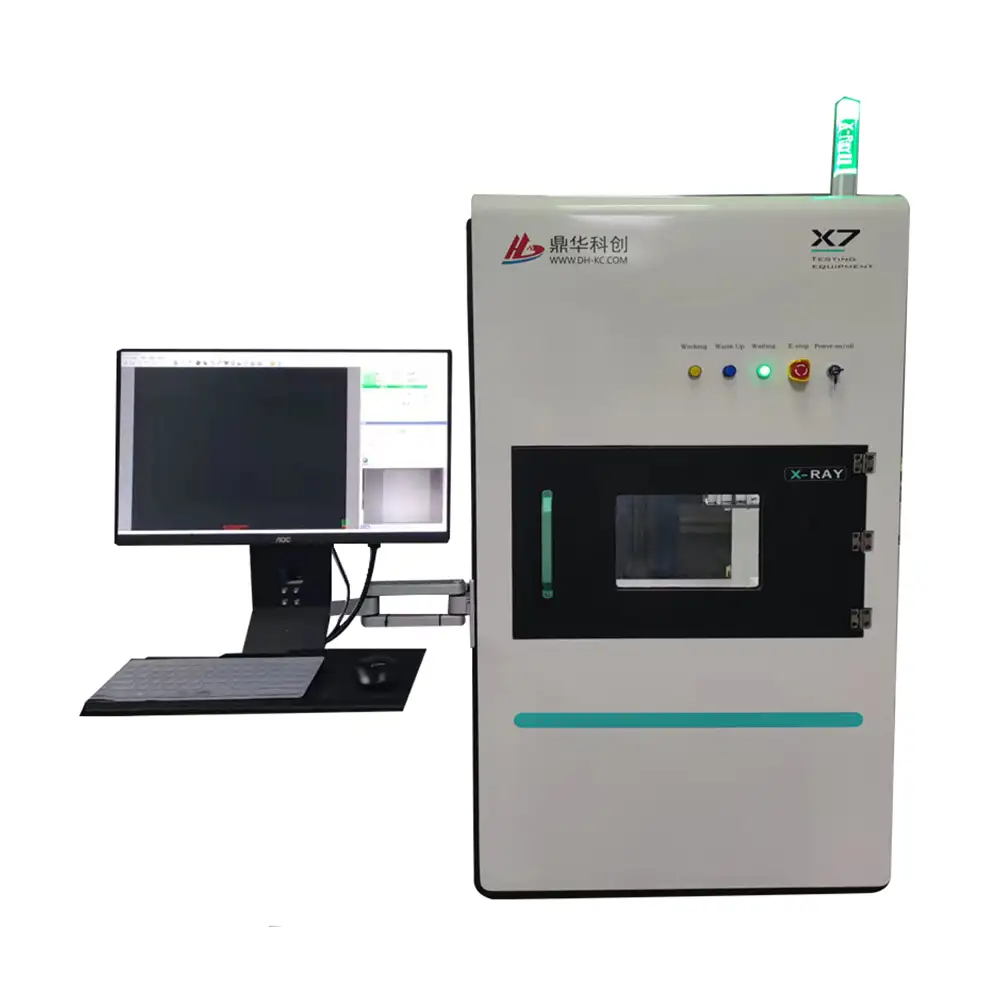

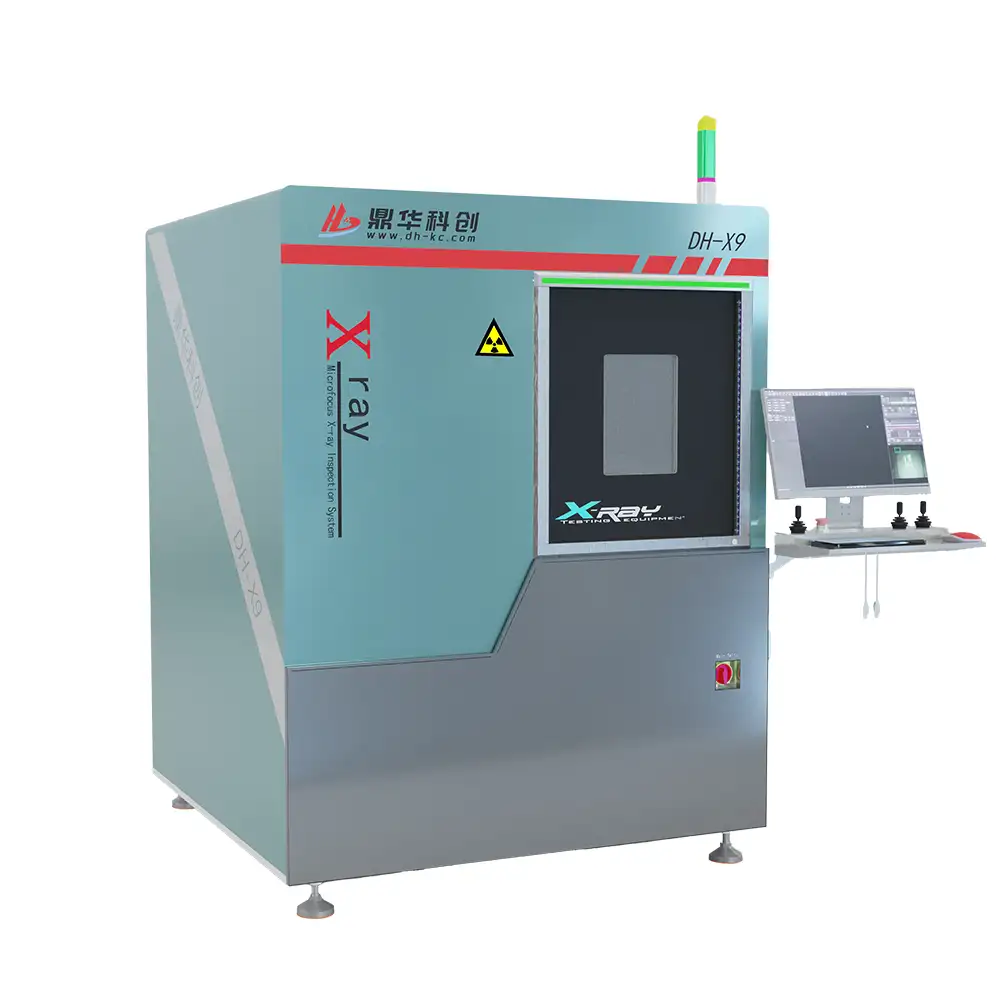

We are a leading manufacturer of BGA rework station, Xray inspection machine, Xray counter machine and automation equipment etc

Where is your factory?

We are located at 4F 6B, Shengzuozhi Technology Park, Xinqiao, Bao’an, Shenzhen, Guangdong, China

Are there over-seas after-sales service centers?

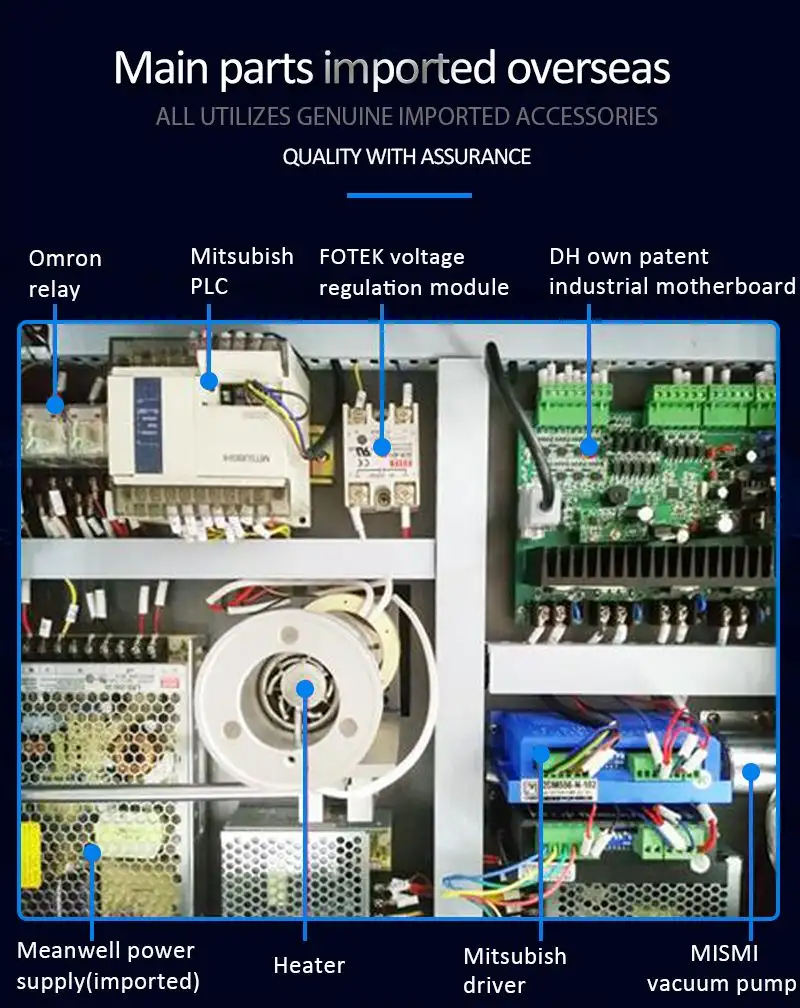

BGA rework station, Xray inspection machine, Xray counter machine and automatic soldering station consist of modularized structures, which are simple to change. So, if machines have a problem, changing its relevant part. We don’t arrange after-sales engineers to always live overseas, but, if our customers need extra service, our engineers can go to on-site

Have you had experiences cooperating with cross-border enterprises by today?

Yes, we do. Such as, Google, Foxconn, Micron, Vestel, Huawei, Kinpo and BYD etc

Online Message