Professional Equipment Manufacturer

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

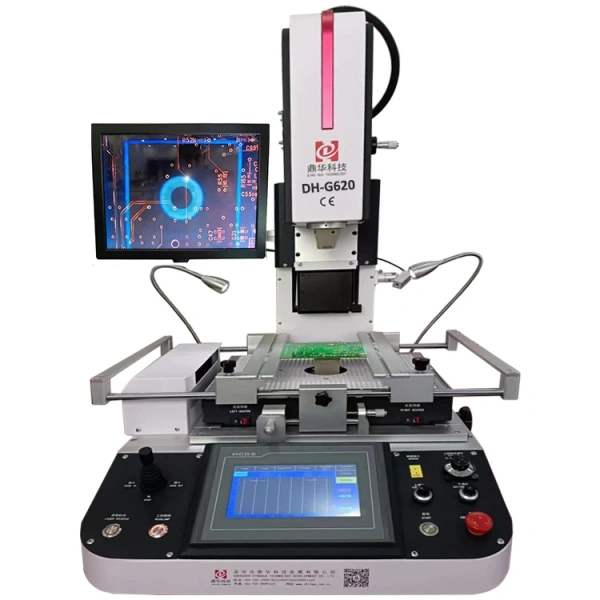

Mastering BGA Rework Stations: Essential Insights for Industrial Equipment Maintenance

2025-04-16

A primary advantage of BGA rework stations is their precision. They allow technicians to accurately manage the heating process, which is crucial for preventing damage to sensitive electronic components. Using a rework station, you can control factors such as temperature and airflow, ensuring that the solder melts evenly without overheating surrounding areas. This precision is vital when working on intricate PCBs that may contain multiple layers and various components.

In addition to precision, BGA rework stations often feature advanced technologies such as infrared heating and hot air rework capabilities. Infrared heating, for example, allows for uniform heating of the entire board, which minimizes thermal stress. Hot air tools, on the other hand, provide versatility by allowing technicians to target specific components for rework, thus avoiding unnecessary heat exposure to adjacent parts. Familiarizing yourself with these technologies can significantly improve your efficiency during repairs.

Another important aspect to consider is the ergonomic design of many modern BGA rework stations. These stations often come equipped with adjustable work surfaces and magnification tools, reducing strain on the technician and increasing comfort during longer repair sessions. This ergonomic focus not only enhances productivity but also contributes to overall job satisfaction in a demanding environment.

For technicians in the industrial equipment maintenance industry, investing time in mastering BGA rework stations can yield substantial benefits. It is essential to engage in continuous learning, whether through formal training, workshops, or self-study. Mastery of BGA rework techniques not only enhances your skill set but also positions you as a valuable resource in your organization, capable of handling complex repair tasks efficiently.

In conclusion, BGA rework stations are a fundamental component of any industrial equipment maintenance toolkit. Their precision, advanced heating technologies, and ergonomic designs make them a preferred choice for technicians focused on delivering high-quality repairs. By investing in proper training and becoming proficient in the use of these stations, professionals can significantly enhance their repair capabilities and contribute to the overall success of their service offerings.

Keywords:

Related News

Essential Insights on Manual BGA Rework Stations for Industrial Equipment Repair

In the realm of industrial equipment repair, a Manual BGA (Ball Grid Array) rework station stands out as an invaluable tool for technicians and engineers. These stations are specifically designed for the rework and repair of BGA components on printed circuit boards (PCBs), a common requirement in various electronic devices and machinery. Understanding how to effectively utilize a Manual BGA rework

From Beginner to Pro: Mastering Your BGA Rework Station for Enhanced Industrial Equipment Repair

From Beginner to Pro: Getting Started with Your BGA Rework Station Table of Contents 1. Introduction to BGA Rework Stations 2. Understanding BGA Rework Technology 3. Essential Tools for Your BGA Rework Station 4. Setting Up Your BGA Rework Station 5. Key Techniques for Effective BGA Rework 6. Troubleshooting Tips for BGA Rework 7. Safety Precautions When Using a BGA Re

Nepcon China

Mastering BGA Rework Stations: Essential Insights for Industrial Equipment Maintenance

When it comes to maintaining and repairing industrial equipment, BGA (Ball Grid Array) rework stations have become indispensable tools. These stations are specifically designed for soldering, removing, and replacing BGA components on printed circuit boards (PCBs). Understanding how to effectively use a BGA rework station can greatly enhance the quality of your repairs and extend the lifespan of yo