Professional Equipment Manufacturer

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

From Beginner to Pro: Mastering Your BGA Rework Station for Enhanced Industrial Equipment Repair

2025-04-23

From Beginner to Pro: Getting Started with Your BGA Rework Station

Table of Contents

- 1. Introduction to BGA Rework Stations

- 2. Understanding BGA Rework Technology

- 3. Essential Tools for Your BGA Rework Station

- 4. Setting Up Your BGA Rework Station

- 5. Key Techniques for Effective BGA Rework

- 6. Troubleshooting Tips for BGA Rework

- 7. Safety Precautions When Using a BGA Rework Station

- 8. Conclusion: Elevate Your BGA Rework Skills

- 9. Frequently Asked Questions (FAQs)

1. Introduction to BGA Rework Stations

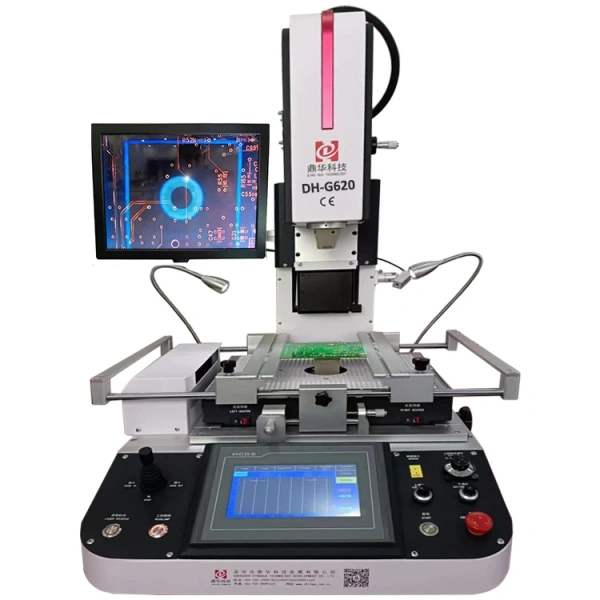

BGA (Ball Grid Array) rework stations are essential tools in the realm of industrial equipment repair, particularly for professionals dealing with complex electronic assemblies. These stations enable technicians to replace, repair, or reflow BGA components efficiently, ensuring that devices function optimally. In this guide, we will delve into everything you need to know to navigate your BGA rework station confidently, from the basics to advanced techniques.

2. Understanding BGA Rework Technology

Before diving into the practical aspects, it is crucial to grasp the underlying technology of BGA rework. BGA packages contain an array of solder balls on the underside, which create connections between the component and the PCB (Printed Circuit Board). Understanding how heat affects the solder balls—causing them to melt and reform—is key to successful rework.

The Importance of Precision in BGA Rework

Precision is paramount when working with BGA components. Even a slight misalignment during the rework process can lead to connection failures or short circuits, impacting the overall functionality of the device. Therefore, having a solid understanding of reflow profiles and solder behavior can significantly enhance your repair outcomes.

3. Essential Tools for Your BGA Rework Station

To achieve the best results with your BGA rework station, equipping yourself with the right tools is imperative. Here’s a list of essential tools that every technician should have:

Soldering Iron with Temperature Control

A reliable soldering iron with adjustable temperature settings is crucial for managing heat levels during the rework process. Different solder types require varying temperatures, so flexibility is key.

Hot Air Rework Station

A hot air rework station is essential for evenly distributing heat across the BGA component. This tool allows for precise control over airflow and temperature, minimizing the risk of damaging surrounding components.

Preheating Plate

Utilizing a preheating plate can significantly improve the rework process by warming the PCB before applying heat to the BGA component. This helps to prevent thermal shock and ensures a smoother reflow process.

Stencils and Solder Paste

Stencils are used to apply solder paste accurately to the PCB. High-quality solder paste ensures reliable connections once the BGA is reattached.

Microscope or Magnification Tool

A microscope or magnification tool aids in inspecting the BGA connections before and after the rework process, ensuring that everything is aligned correctly.

ESD Protection Gear

Electrostatic discharge (ESD) can cause irreversible damage to electronic components. Investing in ESD protection gear is essential to safeguard both you and the components you are working with.

4. Setting Up Your BGA Rework Station

Once you have gathered the necessary tools, the next step involves setting up your BGA rework station effectively. Here are crucial steps to consider:

Organizing Your Workspace

A well-organized workspace enhances efficiency and reduces the likelihood of errors. Keep your tools within reach and maintain a clean area free from dust and debris.

Correctly Positioning Your Equipment

Arrange your hot air rework station and soldering iron at convenient angles. Position your preheating plate under the BGA area to create a seamless workflow.

Ensuring Proper Ventilation

Working with soldering materials can generate fumes. Ensure your workspace is well-ventilated to avoid inhaling harmful substances.

5. Key Techniques for Effective BGA Rework

Mastering BGA rework requires practice and knowledge of various techniques. Here are some crucial methods to enhance your skills:

Reflow Soldering Techniques

Understanding reflow soldering is vital. The process involves heating the PCB and solder balls until the solder melts, creating a strong bond upon cooling. It’s essential to follow a suitable thermal profile to prevent damage to the components.

Component Removal Techniques

When removing BGA components, it's important to apply heat evenly and ensure that the PCB does not experience thermal shock. Using a hot air rework station in conjunction with tweezers can facilitate the removal process.

Proper Alignment for Reattachment

When reattaching a BGA component, ensuring proper alignment is critical. Use alignment tools or templates to guarantee accurate placement before reflowing the solder.

Testing and Validation

After completing the rework, testing the functionality of the repair is crucial. Utilize continuity testers and visual inspections to validate that all connections are secure and functioning correctly.

6. Troubleshooting Tips for BGA Rework

Even with the best techniques, issues may arise during the rework process. Here are some troubleshooting tips to consider:

Common BGA Rework Problems

Some common problems include insufficient solder, misalignment, and bridging between solder balls. Identifying these issues early can save time and prevent further damage.

Strategies for Effective Problem-Solving

When encountering problems, refer back to your thermal profile and ensure that you have applied uniform heat. Reassess your tools and techniques to identify potential areas for improvement.

7. Safety Precautions When Using a BGA Rework Station

Safety should always be a priority when working with electronic devices. Here are some essential safety precautions:

Wear Protective Gear

Always wear appropriate protective gear, including safety glasses and ESD wrist straps, to protect yourself and the components you’re handling.

Maintain a Clean Workspace

Regularly clean your workstation to eliminate potential hazards and ensure that all tools are in good condition.

Handle Tools with Care

Electrical tools can be dangerous if not handled correctly. Always follow the manufacturer’s instructions and exercise caution when using hot equipment.

8. Conclusion: Elevate Your BGA Rework Skills

In summary, mastering your BGA rework station involves understanding the technology, utilizing the right tools, and employing effective techniques. By following the guidelines outlined in this article, you can enhance your skills and achieve better results in your industrial equipment repairs. Remember, practice is essential in refining your abilities, so keep experimenting and learning. With dedication and the right knowledge, you can transition from a beginner to a pro in no time!

9. Frequently Asked Questions (FAQs)

What is a BGA rework station used for?

A BGA rework station is used for repairing and reworking electronic components that use BGA packages, enabling technicians to replace or reflow solder joints effectively.

What tools are essential for BGA rework?

Essential tools include a soldering iron, hot air rework station, preheating plate, stencils, solder paste, magnification tools, and ESD protection gear.

How do I prevent thermal shock during BGA rework?

Prevent thermal shock by using a preheating plate to warm the PCB before applying heat to the BGA component. This gradual heating reduces stress on the board.

What should I do if I encounter bridging during rework?

If bridging occurs, you can carefully remove excess solder using a solder wick or desoldering pump, and then reflow the solder to ensure proper connections.

How can I ensure proper alignment when reattaching a BGA component?

Use alignment tools or templates to ensure the BGA component is correctly positioned before reflowing the solder. Double-check alignment visually for accuracy.

Keywords:

Related News

Essential Insights on Manual BGA Rework Stations for Industrial Equipment Repair

In the realm of industrial equipment repair, a Manual BGA (Ball Grid Array) rework station stands out as an invaluable tool for technicians and engineers. These stations are specifically designed for the rework and repair of BGA components on printed circuit boards (PCBs), a common requirement in various electronic devices and machinery. Understanding how to effectively utilize a Manual BGA rework

From Beginner to Pro: Mastering Your BGA Rework Station for Enhanced Industrial Equipment Repair

From Beginner to Pro: Getting Started with Your BGA Rework Station Table of Contents 1. Introduction to BGA Rework Stations 2. Understanding BGA Rework Technology 3. Essential Tools for Your BGA Rework Station 4. Setting Up Your BGA Rework Station 5. Key Techniques for Effective BGA Rework 6. Troubleshooting Tips for BGA Rework 7. Safety Precautions When Using a BGA Re

Nepcon China

Mastering BGA Rework Stations: Essential Insights for Industrial Equipment Maintenance

When it comes to maintaining and repairing industrial equipment, BGA (Ball Grid Array) rework stations have become indispensable tools. These stations are specifically designed for soldering, removing, and replacing BGA components on printed circuit boards (PCBs). Understanding how to effectively use a BGA rework station can greatly enhance the quality of your repairs and extend the lifespan of yo