Professional Equipment Manufacturer

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

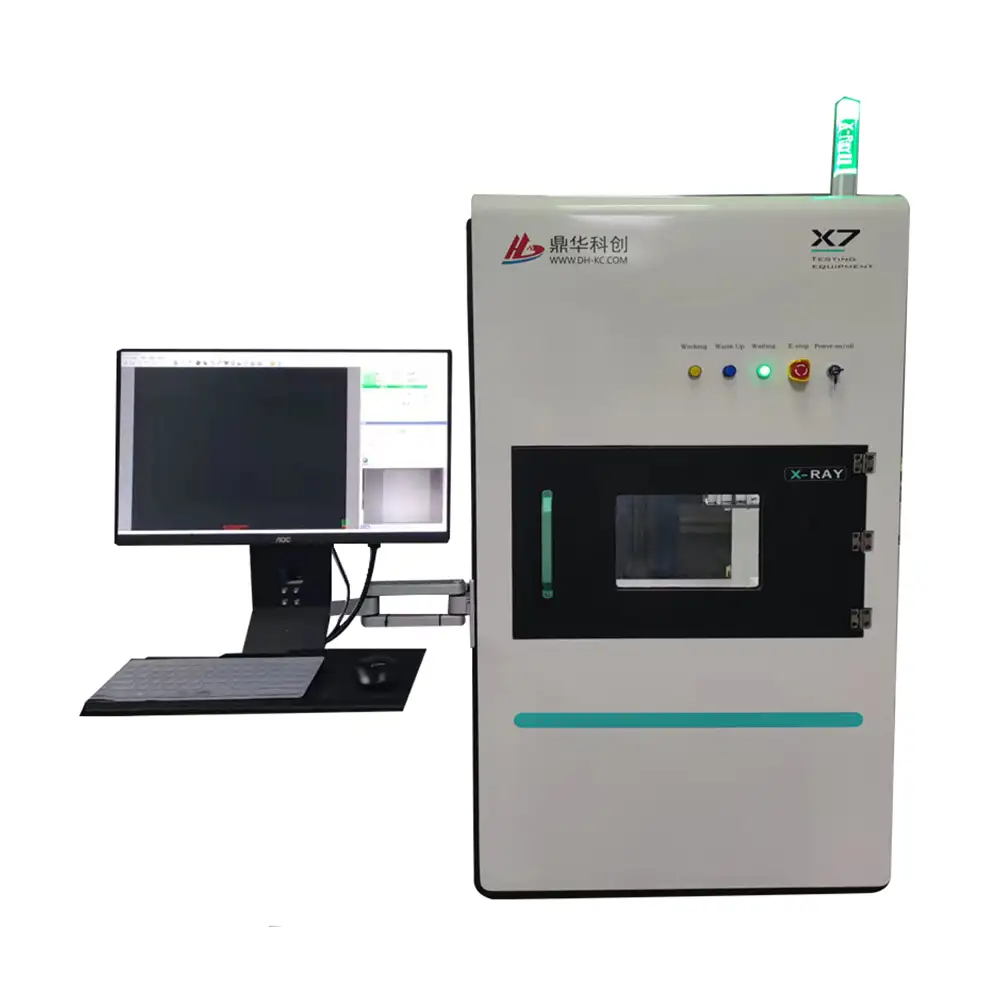

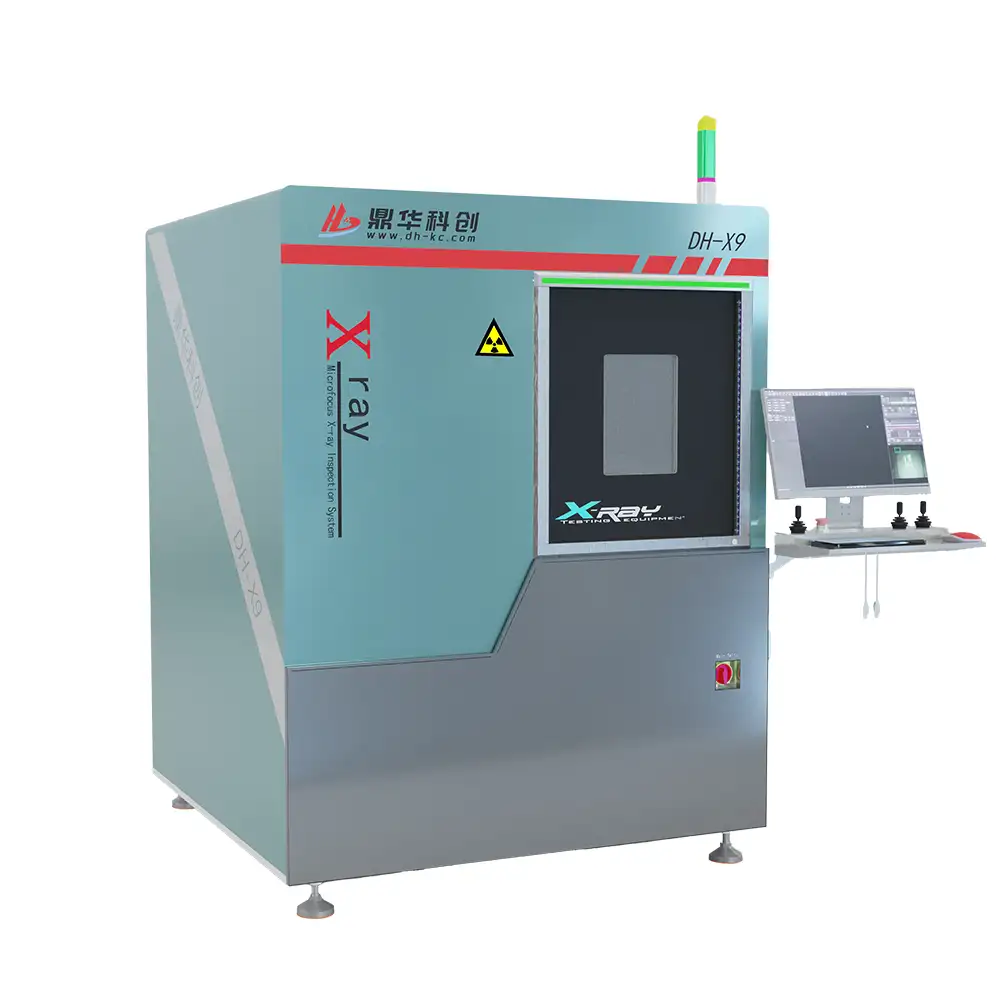

DH-X9 X-Ray PCB inspection

Categories:

Keywords:

Product introduction

Dinghua Xray inspection system DH-X9

Dinghua Technology uses the most advanced equipment and technology to ensure the highest level of quality and precision.

Our X-ray inspection systems are suitable for a wide range of industries, including automotive, electronics, automotive and semiconductor.

In the automotive sector and in the industrial sector, X-ray inspection systems are used to detect defects in components such as airbags, die-casting, metal parts, aluminum parts, etc.

In these industries, our systems detect defects in electronic components, e.g.such as PCBs, capacitors and IC chips. Cracks, die-casting, etc. of aluminum parts.

One advantage of X-ray inspection systems is that they are non-destructive, meaning we do not damage the product being tested.

This saves time because defective parts can be quickly identified and replaced before they cause problems.

| Machine's status | X-ray tube |

| Power supply: AC220V 10A | X-ray tube type:losed |

| Power: 1.9KW | Current: 200ɥA |

| Door opening: method manual | Voltage: 90KV-130KV |

| Detection method:offline | Focus size:5um |

| Dimension: 1475 ×1465 ×1930mm | Geometric magnification: 300times |

| Weight: Approx2100KG | Cooling method:air cooling |

Imaging system | |

| Effective imaging area:130 ×130mm | Radiation tolerance:10000Gy |

| pixel matrix: 1536 ×1536 | Size:176 ×176 ×47 |

| Pixel size:85µm | Detector :New TFT |

| spatial resolution: 5.8lp/mm | Operating temperature: 10-40℃ |

FACTORY WORKSHOP

CUSTOMER TRANSACTION

Adhering to the business principle of mutual benefits, we have had a reliable reputation among our customers because of our professional services, quality products and competitive prices.

CUSTOMER TRANSACTION

We welcome customers at home and abroad to visit our factory to reach long-term cooperation and create success together.

FAQ

Can you make a proof for using automatic soldering station:

Yes, please send us your motherboards and components,we can even customize a jig/fixture which will hold your motherboard & components on Machine’s table for soldering.

What is a BGA reworkstation?

Dinghua BGA rework stations, featured with 3 independent heating-area, PID controlling temperatures, real-time curves displaying on touchscreen, is a station used for various chips and a few components desoldering or soldering.

Are you a manufacturer or a trading company?

We are a leading manufacturer of BGA rework station, Xray inspection machine, Xray counter machine and automation equipment etc

Where is your factory?

We are located at 4F 6B, Shengzuozhi Technology Park, Xinqiao, Bao’an, Shenzhen, Guangdong, China

Are there over-seas after-sales service centers?

BGA rework station, Xray inspection machine, Xray counter machine and automatic soldering station consist of modularized structures, which are simple to change. So, if machines have a problem, changing its relevant part. We don’t arrange after-sales engineers to always live overseas, but, if our customers need extra service, our engineers can go to on-site

Have you had experiences cooperating with cross-border enterprises by today?

Yes, we do. Such as, Google, Foxconn, Micron, Vestel, Huawei, Kinpo and BYD etc

Online Message