Professional Equipment Manufacturer

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

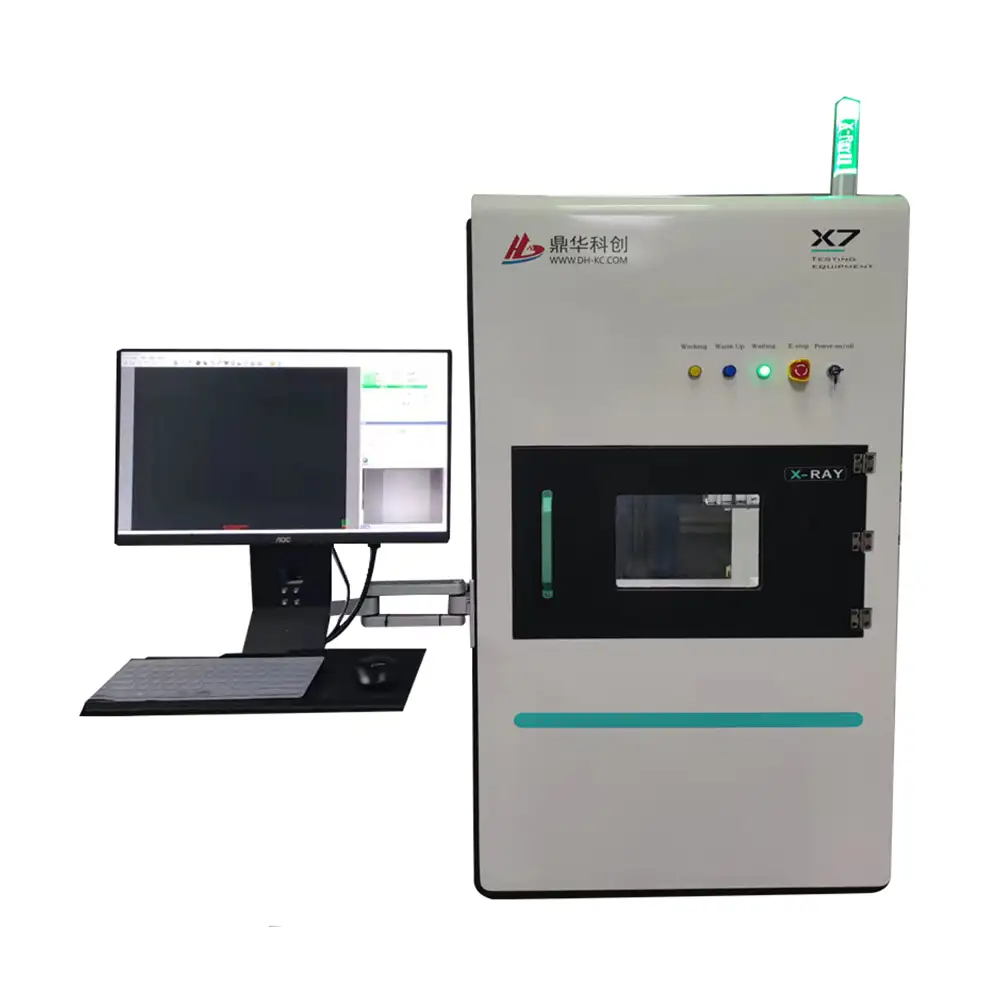

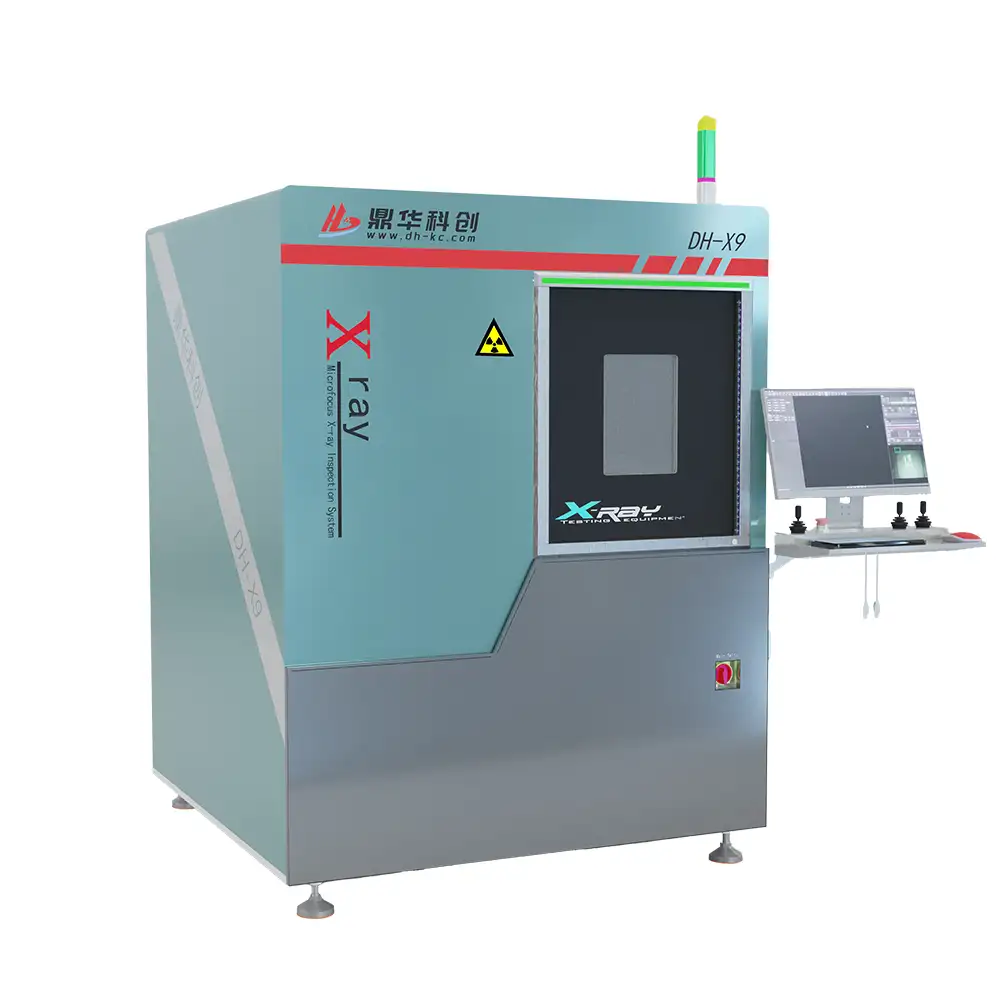

DH-X7 PCB Xray inspection machine

Categories:

Keywords:

Product introduction

|

1. The loading platform can move in the X Y direction |

Greater effective detection range, improving product magnification and detection efficiency (optional 360 º rotary loading stage) |

|

2. Image detector |

Easily observe product side defects, such as BGA solder joints, through-hole tin penetration, etc |

|

3. X-ray source |

Adopting Japanese Hamamatsu enclosed light tube, with long service life and maintenance free |

|

4. X-ray reception |

High definition digital flat panel detector |

|

5. Visual automatic navigation window |

Easy to operate and quickly locate the detection target location |

|

6. Loading platform |

Large detection space, size 450 * 500mm (large industrial control motherboard, LED light strip, etc.) |

|

7. Editable detection program |

Suitable for large-scale automatic detection, improving efficiency, and automatically detecting NG products |

|

8. Rework Digital Library Management |

Savable and editable detection program, detection effect image |

|

9. MWS/ERP system |

Customized access for easy management |

Detailed Images

|

size 1100 ×1200 ×2100mm |

Input voltage AC220V 10A |

|

|

weight about1400KG |

Gross weight about 1600KG |

|

|

Case size 1300 ×1400 ×2200mm |

Power 1.7KW |

|

|

Open mode by hand |

Inspection mode Offline |

|

|

Loading method by hand |

Rights Management Password |

|

|

X-ray tube |

||

|

Tube type Closed |

Tube current 200ɥA |

|

|

Tube voltage 90KV |

Focus 3-5um |

|

|

Cooling mode air cooling |

Geometric magnification 300X |

|

|

Imaging system |

||

|

Detector New TFT |

radiation tolerance 10000Gy |

|

|

Effective imaging area 130 ×130mm |

Protection level lP65 |

|

|

pixel matrix 1536 ×1536 |

Size 176 ×176 ×47 |

|

|

pixel size 85µm |

Weight 3.5KG |

|

|

spatial resolution 5.8lp/mm |

Power 9W |

|

|

Frame rate 20fps |

Operation Temperature 10-40℃ |

|

|

AD conversion bits 16bit |

Storage temperature -10-55℃ |

|

|

data interface Gigabit Ethernet |

Operation humidity 20-90%HP(Frost free) |

|

|

Trigger mode Continuous acquisition, pulse synchronization |

Storage humidity 10-90%HP(Frost free) |

|

|

X-ray energy range 40KV-90KV |

Image Settings Brightness, Contrast, Auto Gain, and Exposure |

|

|

IPC |

||

|

Monitor 21.5-inch high-definition display |

operating system Windows10 64位 |

|

|

Operatiob mode keyboard/Mouse |

Hard disk/memory 1TB/8G |

|

|

Safty |

||

|

Radiation amount |

The steel lead steel protective structure is adopted, and the front door window is made of lead glass for ray protection. At any position 20mm away from the box, the equivalent rate of the tested radiation dose is ≤ 1 μ SV/H meets international standards |

|

|

lead glass window |

Transparent Lead glass, isolating radiation to observe the measured object |

|

|

Safty interlock |

Two high sensitivity limit switches are set at the door opening positions for equipment maintenance and upkeep. Once the door is opened, the X-ray tube will automatically power off immediately |

|

|

Electromagnetic safety door switch |

The observation window is equipped with an electromagnetic switch, and cannot be opened when the X-ray tube is in working state |

|

|

Emergency |

Located next to the operation position, press to immediately power off |

|

|

Visible window |

With a visible and transparent window, it is easy to observe the sample situation directly from the window during equipment operation |

|

|

X-ray tube protection |

Only after turning off the X-ray can you leave the software for other operations |

|

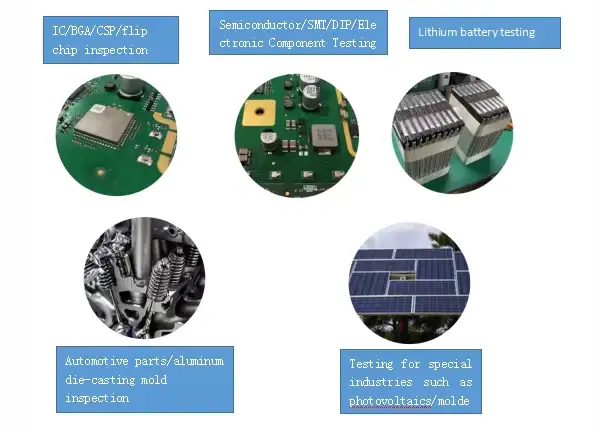

Product application:

X-ray inspection machines play a crucial role in ensuring the safety and security of numerous industries such as

automobile, pharmaceuticals,and communication industries. These machines are designed to detect defects in

products that may pose arisk to consumers.

However, it is important to ensure that the use of X-ray inspection machines is safe for both the operators and

the products being inspected. That is why radiation safety is a top priority when it comes to the use of X-ray

inspection machines.

To guarantee radiation safety, X-ray inspection machine manufacturers follow strict guidelines and regulations

set by organizations such as the International Atomic Energy Agency (IAEA) and the International Electrotechnical

Commission (IEC).

For example, X-ray inspection machines are designed with shielding and safety interlocks to minimize radiation

exposure(X-Ray Radiation Level <1μSv/h.). Operators don't need to wear protective gear such as lead aprons

and goggles to further minimize exposure, because it has been minimized.

FACTORY WORKSHOP

CUSTOMER TRANSACTION

Adhering to the business principle of mutual benefits, we have had a reliable reputation among our customers because of our professional services, quality products and competitive prices.

CUSTOMER TRANSACTION

We welcome customers at home and abroad to visit our factory to reach long-term cooperation and create success together.

FAQ

Can you make a proof for using automatic soldering station:

Yes, please send us your motherboards and components,we can even customize a jig/fixture which will hold your motherboard & components on Machine’s table for soldering.

What is a BGA reworkstation?

Dinghua BGA rework stations, featured with 3 independent heating-area, PID controlling temperatures, real-time curves displaying on touchscreen, is a station used for various chips and a few components desoldering or soldering.

Are you a manufacturer or a trading company?

We are a leading manufacturer of BGA rework station, Xray inspection machine, Xray counter machine and automation equipment etc

Where is your factory?

We are located at 4F 6B, Shengzuozhi Technology Park, Xinqiao, Bao’an, Shenzhen, Guangdong, China

Are there over-seas after-sales service centers?

BGA rework station, Xray inspection machine, Xray counter machine and automatic soldering station consist of modularized structures, which are simple to change. So, if machines have a problem, changing its relevant part. We don’t arrange after-sales engineers to always live overseas, but, if our customers need extra service, our engineers can go to on-site

Have you had experiences cooperating with cross-border enterprises by today?

Yes, we do. Such as, Google, Foxconn, Micron, Vestel, Huawei, Kinpo and BYD etc

Online Message