Professional Equipment Manufacturer

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

The Essential Guide to BGA Soldering Stations for Industrial Equipment Repair

2025-04-02

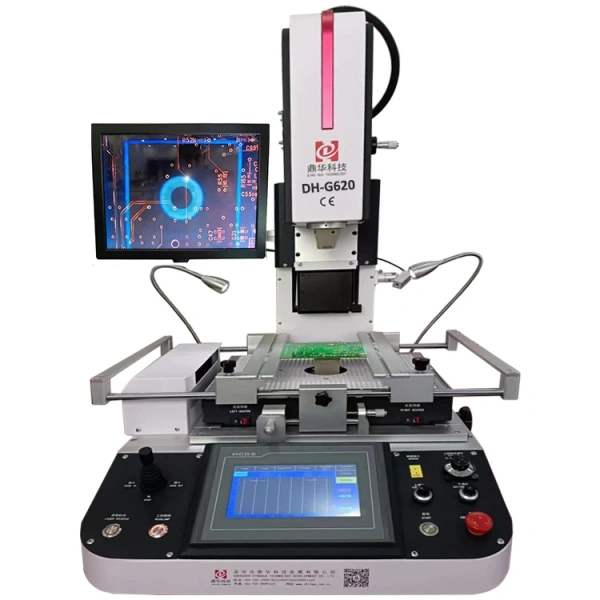

BGA soldering stations are equipped with features that facilitate precise heating and soldering of BGA components. These stations typically include a hot air rework tool and a soldering iron, both of which are essential for handling delicate electronic parts. The hot air tool provides an even distribution of heat, allowing for the safe removal and placement of BGA chips without damaging the surrounding components. On the other hand, the soldering iron is utilized for additional soldering tasks that require precision.

One of the key benefits of using a BGA soldering station is its ability to repair high-density circuit boards. Traditional soldering methods often fall short when dealing with the complexities of BGA components due to their unique arrangements. BGA soldering stations address these challenges by providing controlled heat application, minimizing the risk of overheating and potential damage to the board. This precision not only improves the quality of repairs but also extends the lifespan of the equipment.

Furthermore, a quality BGA soldering station can significantly reduce repair times. The efficiency of the hot air tool combined with the precision of the soldering iron allows technicians to perform complex repairs more quickly than conventional methods would permit. This efficiency is especially critical in industrial settings where downtime can lead to significant losses.

However, it is essential to use BGA soldering stations correctly to achieve the best results. Prior to beginning any repair work, it is vital to ensure that the equipment is properly calibrated. Regular maintenance and calibration of the station help maintain its performance and prolong its lifespan. Additionally, using the appropriate soldering techniques, such as ensuring proper alignment of the BGA components and using the correct temperature settings, is crucial for successful repairs.

In conclusion, investing in a BGA soldering station is an essential step for any service provider involved in the maintenance and repair of industrial equipment. By understanding its functionalities, benefits, and best practices, technicians can ensure high-quality repairs and improve their overall efficiency in the field. Whether you are a seasoned professional or new to the industry, a BGA soldering station will undoubtedly enhance your repair capabilities.

Keywords:

Related News

Essential Insights on Manual BGA Rework Stations for Industrial Equipment Repair

In the realm of industrial equipment repair, a Manual BGA (Ball Grid Array) rework station stands out as an invaluable tool for technicians and engineers. These stations are specifically designed for the rework and repair of BGA components on printed circuit boards (PCBs), a common requirement in various electronic devices and machinery. Understanding how to effectively utilize a Manual BGA rework

From Beginner to Pro: Mastering Your BGA Rework Station for Enhanced Industrial Equipment Repair

From Beginner to Pro: Getting Started with Your BGA Rework Station Table of Contents 1. Introduction to BGA Rework Stations 2. Understanding BGA Rework Technology 3. Essential Tools for Your BGA Rework Station 4. Setting Up Your BGA Rework Station 5. Key Techniques for Effective BGA Rework 6. Troubleshooting Tips for BGA Rework 7. Safety Precautions When Using a BGA Re

Nepcon China

Mastering BGA Rework Stations: Essential Insights for Industrial Equipment Maintenance

When it comes to maintaining and repairing industrial equipment, BGA (Ball Grid Array) rework stations have become indispensable tools. These stations are specifically designed for soldering, removing, and replacing BGA components on printed circuit boards (PCBs). Understanding how to effectively use a BGA rework station can greatly enhance the quality of your repairs and extend the lifespan of yo