Professional Equipment Manufacturer

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

BGA Rework Machines: Essential Tools for Reliable Technical Support

2025-07-30

BGA Rework Machines: Essential Tools for Reliable Technical Support

Table of Contents

- Introduction to BGA Rework Machines

- The Importance of BGA Rework Machines in Technical Support

- How BGA Rework Machines Work

- Types of BGA Rework Machines

- Benefits of Using BGA Rework Machines

- Applications of BGA Rework Machines

- Maintenance Tips for BGA Rework Machines

- The Future of BGA Rework Technology

- Conclusion

- FAQs

Introduction to BGA Rework Machines

BGA (Ball Grid Array) rework machines are specialized tools designed to facilitate the repair and rework of BGA components on printed circuit boards (PCBs). These machines play a crucial role in the repair and maintenance of industrial equipment, ensuring that technical support teams can efficiently handle various electronic components. With the rapid advancement of technology and the increasing complexity of electronic devices, the demand for reliable and efficient BGA rework machines has surged.

The Importance of BGA Rework Machines in Technical Support

In the world of technical support, the ability to perform precise repairs is paramount. BGA rework machines provide significant advantages, including:

- **Precision**: These machines allow for extremely accurate placement and soldering of BGA components, minimizing the risk of damage during repairs.

- **Efficiency**: By streamlining the rework process, technicians can save time and reduce downtime for equipment, which is vital in industrial settings.

- **Cost-Effectiveness**: Repairing rather than replacing faulty components can lead to substantial cost savings for organizations, making BGA rework machines an investment worth considering.

How BGA Rework Machines Work

BGA rework machines utilize a combination of heat and controlled movement to remove and replace BGA components. The process generally involves the following steps:

1. **Preparation**: The PCB is cleaned and prepped for the rework process. This often includes removing any old solder and ensuring the pad surfaces are ready.

2. **Heating**: The machine applies heat to the BGA component, melting the solder balls underneath it.

3. **Removal**: Once the solder is melted, the component can be lifted off using a vacuum or mechanical arm.

4. **Placement**: A new BGA component is positioned over the pads, and the machine applies heat again to solder it into place.

5. **Cooling**: Finally, the assembly is allowed to cool, solidifying the solder and securing the component.

Types of BGA Rework Machines

Understanding the different types of BGA rework machines available can help in selecting the right one for specific needs.

Manual BGA Rework Machines

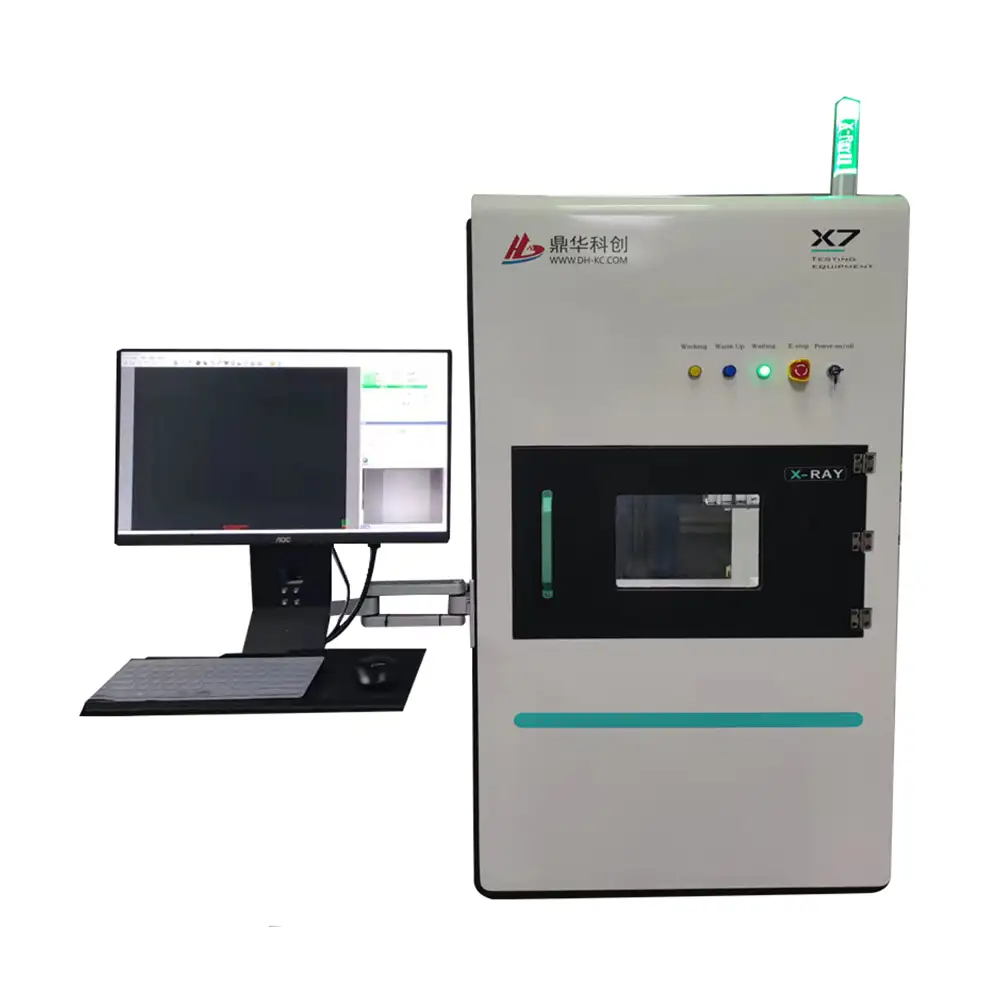

Manual BGA rework machines require human intervention for each step of the process. While they may be less expensive and suitable for small operations, they require skilled technicians to ensure precision and minimize the risk of errors.

Semi-Automatic BGA Rework Machines

Semi-automatic machines offer a balance between manual effort and automation. They assist technicians by automating some processes, like heating and vacuuming, while still requiring manual placement and adjustments. This type of machine is ideal for medium-sized operations looking to improve efficiency without a significant investment.

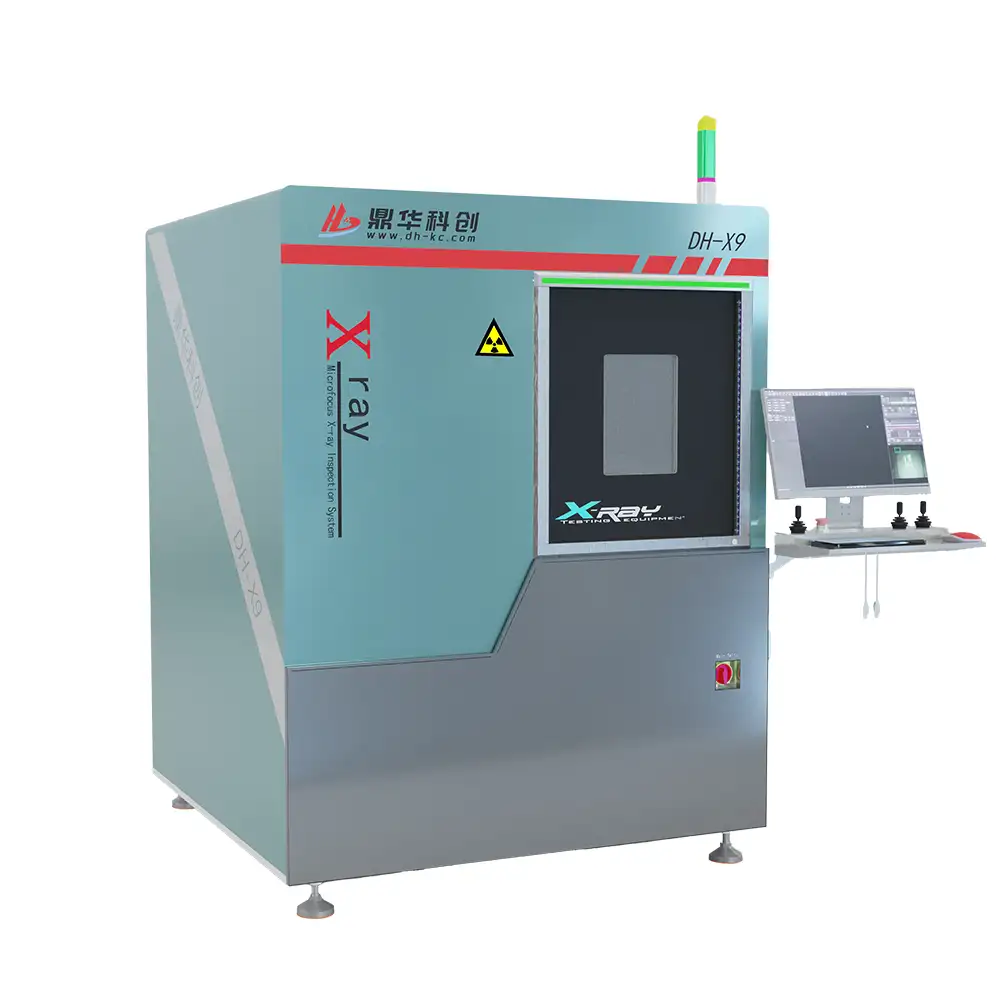

Fully Automatic BGA Rework Machines

Fully automatic BGA rework machines are the most advanced option, capable of independently managing the entire rework process. These machines are equipped with sophisticated software and sensors, allowing them to perform high-precision tasks with minimal human intervention. They are perfect for large-scale operations that demand high efficiency and accuracy.

Benefits of Using BGA Rework Machines

The incorporation of BGA rework machines into technical support processes offers numerous benefits:

- **Enhanced Repair Quality**: The precision offered by these machines significantly reduces the chances of defects during rework.

- **Reduced Lead Times**: Faster repair times lead to improved operational efficiency and decreased equipment downtime.

- **Increased Technician Productivity**: Automation facilitates a smoother workflow, allowing technicians to focus on higher-level tasks.

- **Sustainability**: By promoting repair over replacement, BGA rework machines contribute to waste reduction and sustainable practices in the industry.

Applications of BGA Rework Machines

BGA rework machines find applications in various industries, including:

- **Electronics Manufacturing**: Essential for repairs on PCBs in consumer electronics, automotive, and telecommunications.

- **Aerospace and Defense**: Critical for maintaining the reliability and safety of components used in aircraft and military devices.

- **Medical Devices**: Vital for ensuring the functionality of medical electronics that require high precision and reliability.

Maintenance Tips for BGA Rework Machines

To keep BGA rework machines operating at peak performance, regular maintenance is crucial. Consider the following tips:

1. **Regular Calibration**: Ensure the machine is calibrated to maintain precision in soldering temperature and placement.

2. **Routine Cleaning**: Keep the machine clean from dust, solder debris, and other contaminants that may interfere with its operation.

3. **Software Updates**: Keep the machine’s software up to date to benefit from new features and improvements that enhance performance.

4. **Inspect Components**: Regularly check and replace worn-out parts, such as heating elements and nozzles, to prevent operational issues.

The Future of BGA Rework Technology

The future of BGA rework machines is promising, with ongoing advancements in technology paving the way for even greater efficiency and precision. Developments in artificial intelligence (AI) and machine learning are expected to play a significant role in optimizing rework processes, enhancing accuracy, and reducing the likelihood of human error. Moreover, as the market for electronic devices continues to grow, the demand for innovative BGA rework solutions will also increase, driving further research and development in this field.

Conclusion

BGA rework machines are indispensable tools for any technical support operation involved in the repair and maintenance of industrial equipment. Their ability to enhance precision, efficiency, and cost-effectiveness makes them a wise investment for organizations looking to improve their service capabilities. As technology progresses, we can anticipate even more advanced solutions that will further revolutionize the way we approach electronic repairs. Investing in quality BGA rework machines is not just about keeping pace with industry standards; it's about ensuring reliability and excellence in technical support.

FAQs

1. What is a BGA rework machine?

BGA rework machines are specialized tools designed to repair and replace BGA components on PCBs. They utilize heat and controlled movement to remove old components and solder new ones.

2. What are the benefits of using BGA rework machines?

These machines enhance repair quality, reduce lead times, increase technician productivity, and promote sustainability by enabling repairs instead of replacements.

3. What types of BGA rework machines are available?

There are three main types: manual, semi-automatic, and fully automatic BGA rework machines, each offering different levels of automation and precision.

4. How do I maintain my BGA rework machine?

Regular calibration, routine cleaning, software updates, and inspection of components are crucial for maintaining optimal performance.

5. In which industries are BGA rework machines used?

BGA rework machines are widely used in electronics manufacturing, aerospace and defense, and the medical device industry, among others.

Keywords:

Related News

BGA Rework Machines: Essential Tools for Reliable Technical Support

BGA Rework Machines: Essential Tools for Reliable Technical Support Table of Contents Introduction to BGA Rework Machines The Importance of BGA Rework Machines in Technical Support How BGA Rework Machines Work Types of BGA Rework Machines Manual BGA Rework Machines Semi-Automatic BGA Rework Machines Fully Automatic BGA Rework Machines

Essential Insights into BGA Soldering Stations for Industrial Equipment Repair

BGA (Ball Grid Array) soldering stations are specialized tools designed for the precise soldering and reworking of electronic components that utilize a ball grid array package. These stations are integral to the maintenance and repair of industrial equipment, as they enable technicians to efficiently handle delicate soldering tasks with accuracy and speed. One of the primary advantages of a BGA so

How to Choose the Right BGA Repair Station for Your Needs

How to Choose the Right BGA Repair Station for Your Needs Table of Contents Understanding BGA Repair: The Basics The Importance of Quality in BGA Repair Types of Services Offered by BGA Repair Stations Evaluating Technology and Equipment The Role of Skilled Technicians in BGA Repair Customer Support: A Crucial Factor Understanding Costs and Estimates Making the R

Understanding BGA Reballing Stations: Essential Tools for Effective Industrial Equipment Repair

The BGA (Ball Grid Array) reballing station is an essential tool for professionals in the industrial equipment repair industry, particularly when dealing with motherboards and other electronic components. This advanced repair technique is crucial for ensuring the long-term performance and reliability of critical devices. BGA packages are commonly used in modern electronics due to their ability to