Professional Equipment Manufacturer

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

How to Choose the Right BGA Repair Station for Your Needs

2025-07-16

How to Choose the Right BGA Repair Station for Your Needs

Table of Contents

- Understanding BGA Repair: The Basics

- The Importance of Quality in BGA Repair

- Types of Services Offered by BGA Repair Stations

- Evaluating Technology and Equipment

- The Role of Skilled Technicians in BGA Repair

- Customer Support: A Crucial Factor

- Understanding Costs and Estimates

- Making the Right Decision for Your Needs

- Frequently Asked Questions

Understanding BGA Repair: The Basics

Ball Grid Array (BGA) repair is a specialized service focusing on the rework and repair of BGA components on printed circuit boards (PCBs). This method is crucial in the maintenance of various electronic devices, especially in industries reliant on reliable performance and minimal downtime. Understanding the basics of BGA repair helps in identifying a repair station that meets specific requirements.

What is BGA Repair?

BGA repair involves the removal and replacement of BGAs on circuit boards. These components are typically mounted using solder balls, making them challenging to work with when issues arise. The repair process often requires precision, advanced tools, and experienced technicians to ensure that the circuit board functions correctly after servicing.

Why is BGA Repair Important?

As technology continues to evolve, the components on circuit boards become more intricate. BGA repairs are vital for extending the lifecycle of electronic equipment, reducing waste, and ensuring that devices operate efficiently. Selecting the right repair station can significantly impact the longevity and performance of your equipment.

The Importance of Quality in BGA Repair

Quality is a non-negotiable factor in BGA repair. Poor quality repairs can lead to recurring failures and increased costs over time. Here, we explore what quality means in the context of BGA repair.

Quality Assurance Processes

A reputable BGA repair station will have stringent quality assurance protocols in place. This includes regular checks, the implementation of industry standards, and certifications that demonstrate their commitment to excellence. Look for certifications such as ISO 9001, which indicates a robust quality management system.

Inspecting Repair Outcomes

Before settling on a repair station, inquire about their inspection processes post-repair. A thorough inspection ensures that the BGA components are functioning as intended. Stations that offer a warranty on their work can provide additional peace of mind.

Types of Services Offered by BGA Repair Stations

Different BGA repair stations offer varying services. It's essential to understand which services are crucial for your needs.

Standard BGA Rework Services

Standard services typically include BGA replacement, solder ball replacement, and PCB repairs. Each of these procedures requires specialized skills, so ensure the station you choose has experience in your specific type of repair.

Advanced Repair Techniques

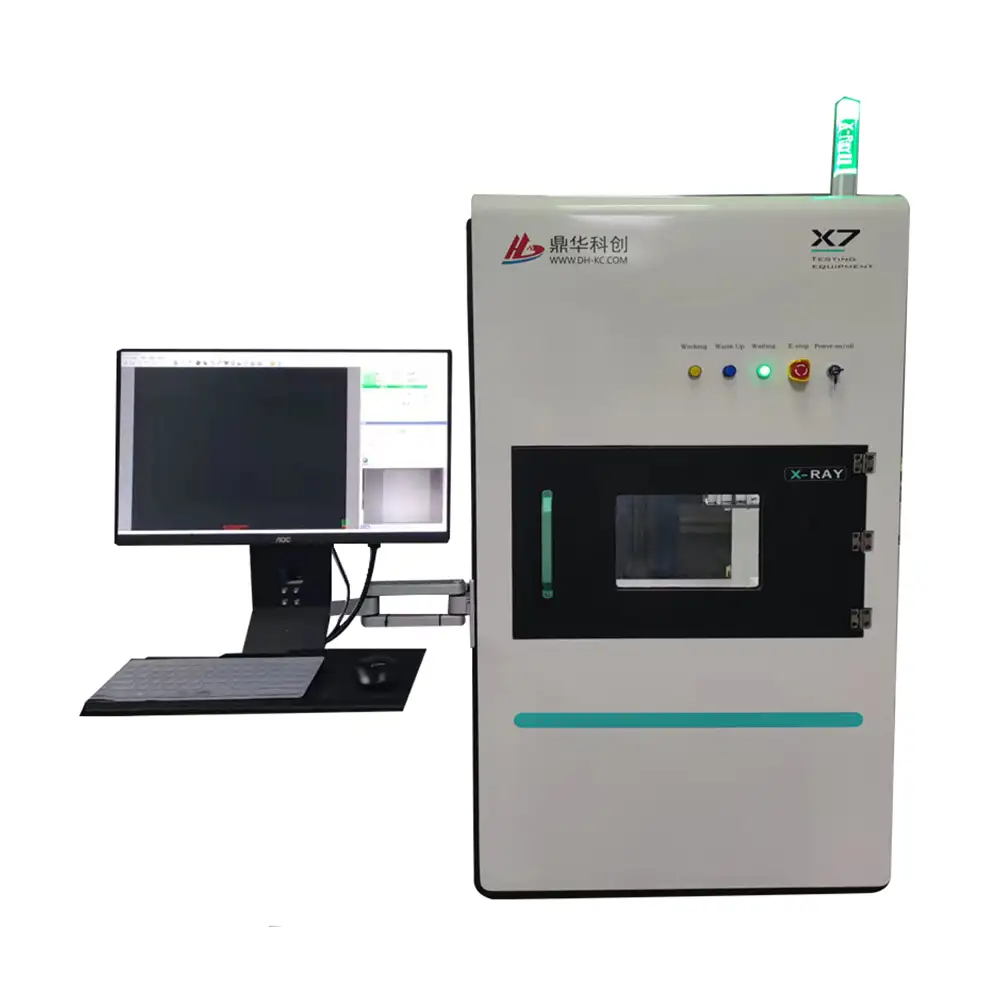

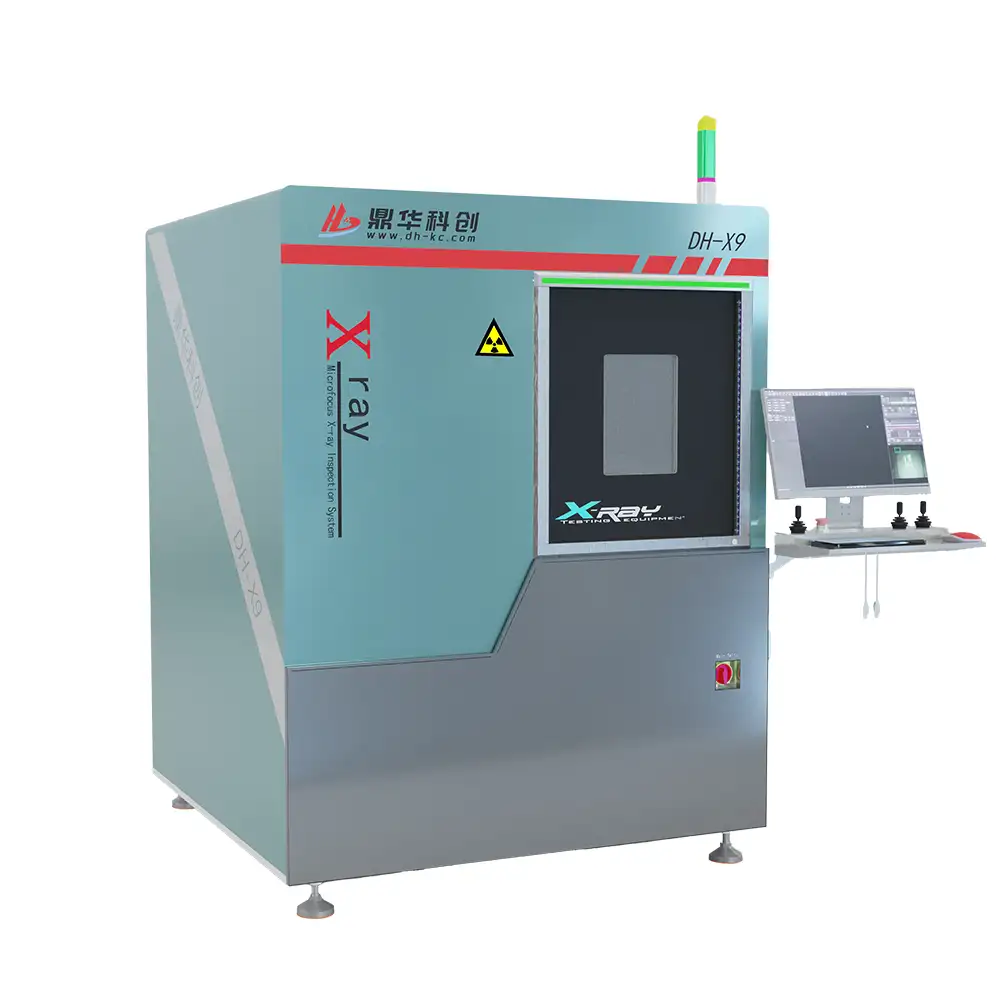

Some stations may offer advanced techniques such as X-ray inspection, reballing, and BGA reflow. If your equipment requires these services, select a station equipped with the necessary technology and skilled personnel.

Evaluating Technology and Equipment

The technology used by a BGA repair station can significantly impact the quality and speed of their services.

State-of-the-Art Equipment

Investigate the types of equipment the station uses. High-quality rework stations, soldering machines, and inspection tools are indicators of a professional setup. Advanced equipment ensures precision and minimizes the risk of damage during repairs.

Software and Monitoring Tools

In addition to physical equipment, consider the software used for monitoring and quality control during repairs. Stations that utilize sophisticated software for tracking repairs and outcomes can offer better transparency and reliability.

The Role of Skilled Technicians in BGA Repair

The expertise of technicians plays a vital role in the quality of BGA repairs.

Training and Certifications

Ensure that the technicians at the repair station have undergone proper training and hold relevant certifications. Their skills in handling intricate components directly influence repair quality.

Experience Matters

Experience is essential when it comes to BGA repairs. Technicians with years of practice are likely to handle unexpected issues more effectively. Ask about the technicians’ experience levels and any specialized training they may have received.

Customer Support: A Crucial Factor

A reliable BGA repair station should provide excellent customer support.

Inquiries and Communication

Evaluate how the repair station handles inquiries. Prompt responses indicate a commitment to customer service. Clear communication regarding repair processes and timelines is essential for managing expectations.

Post-Repair Support

Look for stations that offer post-repair support. This includes guidance on maintenance and troubleshooting, which can be invaluable in maximizing the lifespan of your repaired equipment.

Understanding Costs and Estimates

The cost of BGA repairs can vary significantly depending on the complexity of the work required.

Requesting Quotes

When selecting a repair station, request detailed quotes that break down labor, parts, and additional fees. This transparency will help you gauge the total cost and avoid surprises later on.

Comparing Costs

While cost should not be the only consideration, it is crucial to compare estimates from different repair stations. However, remember that the cheapest option may not always offer the best quality.

Making the Right Decision for Your Needs

With all factors considered, making an informed decision is essential.

Assessing Your Specific Needs

Evaluate your specific requirements based on the type of equipment you operate and the nature of the repairs needed. Tailoring your search to these needs will help narrow down your options.

Trust Your Instincts

Finally, trust your instincts. A repair station that feels right in terms of communication, professionalism, and expertise is likely to be a good fit for your needs.

Frequently Asked Questions

1. What is the average turnaround time for BGA repairs?

Turnaround times can vary depending on the repair station and the complexity of the repair. Generally, you can expect repairs to take anywhere from a few days to a couple of weeks.

2. Are all BGA repair stations the same?

No, BGA repair stations can vary greatly in terms of technology, expertise, and services offered. It's important to research and choose one that fits your specific needs.

3. How do I know if a BGA repair station is reputable?

Look for customer reviews, industry certifications, and their warranty policies. A reputable station will be open to discussing their processes and showcasing their expertise.

4. Can I get a warranty on BGA repairs?

Many repair stations offer warranties on their work. Always ask about warranty policies before committing to a repair.

5. What should I do if I have further issues after repair?

If you experience further issues post-repair, reach out to the repair station immediately. A good station will offer support and may honor warranty terms.

Conclusion

Choosing the right BGA repair station is a critical decision that can influence the operational efficiency of your equipment. By considering factors like quality assurance, technology, technician expertise, customer support, and cost, you can make an informed choice that meets your needs. Investing the time to find a reputable station will ultimately lead to better repair outcomes and prolonged equipment lifespan. Take the necessary steps today to ensure your BGA repair needs are met with the highest standards.

Keywords:

Related News

How to Choose the Right BGA Repair Station for Your Needs

How to Choose the Right BGA Repair Station for Your Needs Table of Contents Understanding BGA Repair: The Basics The Importance of Quality in BGA Repair Types of Services Offered by BGA Repair Stations Evaluating Technology and Equipment The Role of Skilled Technicians in BGA Repair Customer Support: A Crucial Factor Understanding Costs and Estimates Making the R

Understanding BGA Reballing Stations: Essential Tools for Effective Industrial Equipment Repair

The BGA (Ball Grid Array) reballing station is an essential tool for professionals in the industrial equipment repair industry, particularly when dealing with motherboards and other electronic components. This advanced repair technique is crucial for ensuring the long-term performance and reliability of critical devices. BGA packages are commonly used in modern electronics due to their ability to

The Ultimate Guide to Choosing the Right Automatic BGA Rework Station

The Ultimate Guide to Choosing the Right Automatic BGA Rework Station Introduction to BGA Rework Stations In the world of electronics manufacturing and repair, **Ball Grid Array (BGA)** components require specialized attention. The automatic BGA rework station is an indispensable tool, enabling technicians to efficiently repair, replace, and rework BGA components on PCBs (Printed Circuit Board

Mastering Manual BGA Rework Stations for Precision Repairs

Manual BGA (Ball Grid Array) rework stations are essential tools in the field of electronic equipment repair and maintenance. These sophisticated systems allow technicians to precision-repair soldered connections for BGA components on printed circuit boards (PCBs), which are commonly found in various industrial equipment. The ability to perform such repairs manually is crucial for extending the li