1. Nozzle with Reflow Vent

1) All the Nozzles are made by Titanium Alloy.

2) Top Nozzle has Reflow Vent to prevent the damage to surrounding components.

3) Magnetic Nozzle, Easy to install / adjust / change.

Professional Equipment Manufacturer

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

2025-06-24

Dinghua DH-5830 BGA Rework Station

This machine is for repairing motherboard IC/Chip/Chipset of Laptop, Mobile, PC, iPhone, Xbox, etc. With features 3-heater(2xHot air+IR Preheating), embedded Smart PC, Auto Profile, Cooling Fan, Micro hot-air adjustment, Vacuum Pick-up & Place, Universal Support for most of the PCB Size/Shape.

| Total Power | 5500W |

| Top heater Power | 1200W (1st Hot air heater) |

| Bottom Heater | 1200W(2nd hot air heater), 3000W (IR preheat) |

| Temperature Accuracy | ±2℃ |

| Power Supply | AC220V±10% 50Hz |

| Dimension | 700x760x580mm (L*W*H) |

| Temperature Profile Storage | 50,000 groups |

| Operation Mode | Manual+Touchscreen |

| PCB Support | V-groove + universal fixture + 5-points support + Adjustable in X direction |

| Temperature Control | K-type Thermocouple + Closed Loop |

| PCB Size | Max.410x370mm, Min. 22x22mm |

| BGA Chip | 2x2mm-80x80mm |

| Minimum Chip Spacing | 0.15mm |

| External connector for temperature testing | 1pcs or Customized |

| Net Weight | 35KG |

Motherboard of computer,smartphone,laptop,digital camera ,air conditioner,TV and other electronic equipments from medical industry,communication industry,automobile industry,etc.

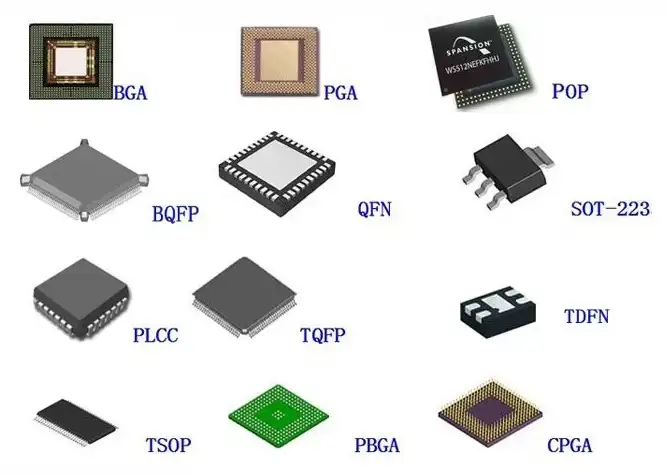

Wide range of application: BGA, PGA, POP,BQFP, QFN, SOT- 223, PLCC, TQFP, TDFN, TSOP, PBGA, CPGA, LED chip.

Manual BGA rework station:For the critical reballing process, the manual station includes a complete stencil kit with aluminum frames holding precision-etched stainless steel templates for common BGA pitch sizes. The solder ball placement jig features micrometer-adjustable guides to ensure accurate alignment over the component, with magnetic fixation holding the stencil securely during ball distribution. A specially designed solder ball dispenser bottle with fine-tip applicator allows controlled placement of replacement spheres, while a static-safe brush assists in final distribution across the array pattern. The station stores all these accessories in dedicated compartments with foam inserts, keeping tools organized and protected between uses.

Process control relies on the technician's skill augmented by the station's measurement tools. A handheld infrared thermometer with laser targeting provides spot temperature readings of components and board areas, while a built-in digital timer helps track critical phases of the rework process. The station includes various nozzle sizes for the rework tool to accommodate different component dimensions, with color-coded collars indicating temperature ranges for quick visual reference during operation. A flip-up soldering iron holder positions a precision temperature-controlled iron ready for touch-up work, completing the thermal toolset for comprehensive BGA rework capability.

The physical construction emphasizes durability and workspace efficiency, with a heavy-gauge steel frame supporting a high-temperature work surface resistant to flux and solder splatter. The integrated fume extraction arm adjusts to multiple positions, capturing vapors directly at the work point without interfering with tool access. Tool hangers and accessory racks keep all implements within easy reach, while the non-slip rubber matting prevents component movement during delicate operations. The entire station occupies a compact footprint suitable for bench-top use, with all electrical components featuring ESD-safe grounding for sensitive electronic work.

Operator safety receives careful consideration in the design, with silicone-insulated tool handles protecting against accidental burns and the hot air tool's auto-cooling function preventing heat buildup when idle. The fume extraction system incorporates replaceable activated carbon filters to remove harmful flux vapors, while the preheater plate includes over-temperature protection that automatically cycles power if unsafe conditions develop. Bright LED task lighting illuminates the work area without creating glare or shadows that could interfere with visual alignment tasks.

Keywords:

Manual BGA rework station

Related News

For the critical reballing process, the manual station includes a complete stencil kit with aluminum frames holding precision-etched stainless steel templates for common BGA pitch sizes.

The Essential Guide to BGA Rework Stations: Boosting Your Equipment Maintenance Strategy

The Essential Guide to BGA Rework Stations: Boosting Your Equipment Maintenance Strategy Table of Contents What is BGA Rework? Importance of BGA Rework Stations in Equipment Maintenance Types of BGA Rework Stations Key Features to Consider When Choosing a BGA Rework Station Step-by-Step BGA Rework Process Common Issues in BGA Rework and Their Solutions Best Practices for Maintaining BGA Rework St

Maximizing Efficiency with BGA Rework Stations for Industrial Maintenance

In the realm of industrial equipment maintenance, BGA rework stations are indispensable tools that facilitate the repair and replacement of BGAs—components prevalent in modern electronic devices. These devices are often critical to the functionality of various industrial machines, making efficient maintenance a priority for service providers. A BGA rework station is designed to handle the specific

The Crucial Role of BGA Rework Machines in Modern Industrial Equipment Repair

The Crucial Role of BGA Rework Machines in Modern Industrial Equipment Repair Table of Contents 1. Introduction to BGA Rework Machines 2. Understanding BGA Technology 3. Importance of BGA Rework Machines in Industrial Equipment Repair 4. How BGA Rework Machines Work 4.1. Key Components of BGA Rework Machines 4.2. The BGA Rework Process Explained 5. Advantages of Using BGA Rework Machines 5.1. Incr