Professional Equipment Manufacturer

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Tester for solder flux

Categories:

Keywords:

Product introduction

| category | Laser thickness gauge | SPI |

| Display mode | display | SPI-6500 |

| Specification | 400*550*360 |

Product details of 3D solder paste thickness gauge

Product features

1. Use an original high-definition color camera imported from Germany to ensure high accuracy and stability of the test.

2. It adopts micro-power consumption level two-level laser, which is less affected by external environmental light sources and has long stable life.

3. Using flexible hardware design, light source, laser and camera, PCB boards of different colors can be tested.

4. The software analysis conditions are based on the database, and the early warning function is implemented based on the analysis conditions, which is intuitive and easy to understand.

5. Powerful report analysis function, automatically generate R-Chart, X-Bar, and automatically calculate CPK.

6. Export detailed and complete SPC reports to completely avoid the disadvantages of handwritten reports.

7. The software adopts a simple and practical concept and focuses on high-precision design for testing. The repetition accuracy of the correction block reaches plus or minus 0.001mm.

Product parameters

1. Application scope: solder paste, red glue

2. Measurement items: Thickness. Area. Volume. 3D shape. Plane distance.

3. Measurement principle: Laser 3-angle function method measurement automatically calculates and displays the PCB deformation or tilt angle n

4. Software language: Chinese/English

6. Lighting source: white high-brightness LEDn

7. Measurement light source: red laser module n Y-axis movement range: 50 mmn

8. Measurement method: automatic full-screen measurement. Automatic measurement by frame selection. Manual measurement by frame selection n

9. Field of view: 5mm*7mmn

10. Camera pixels: 3 million/field of view n

11. Maximum resolution: 0.1umn

12. Scanning spacing: 4 um /8 um /10 um /12 umn

13. Repeated measurement accuracy: height less than plus or minus 1um, area <1%, volume <1%n Magnification: 50Xn

14. Measurable height: 5 mmn

15. Measurement speed: 250Profiles/sn

16. 3D mode: 3 different 3D simulation diagrams: surface, line and point, can be zoomed and rotated n

17. Software: Production line data, printing data, solder paste data, stencil data, measurement results are independently analyzed, X-Bar&R chart analysis, histogram analysis & Ca/Cp/Cpk output, Sigma automatic judgment

18. Operating system: Windows7n

19. Computer system: dual-core P4, 2G memory, 20-inch LCDn

20. Power supply: 220V 50/60Hzn

21. Power consumption: 300Wn

22. Weight: about 35KGn

23. Overall dimensions: L*W*H (400 mm *550 mm *360 mm)

FACTORY WORKSHOP

CUSTOMER TRANSACTION

Adhering to the business principle of mutual benefits, we have had a reliable reputation among our customers because of our professional services, quality products and competitive prices.

CUSTOMER TRANSACTION

We welcome customers at home and abroad to visit our factory to reach long-term cooperation and create success together.

FAQ

Can you make a proof for using automatic soldering station:

Yes, please send us your motherboards and components,we can even customize a jig/fixture which will hold your motherboard & components on Machine’s table for soldering.

What is a BGA reworkstation?

Dinghua BGA rework stations, featured with 3 independent heating-area, PID controlling temperatures, real-time curves displaying on touchscreen, is a station used for various chips and a few components desoldering or soldering.

Are you a manufacturer or a trading company?

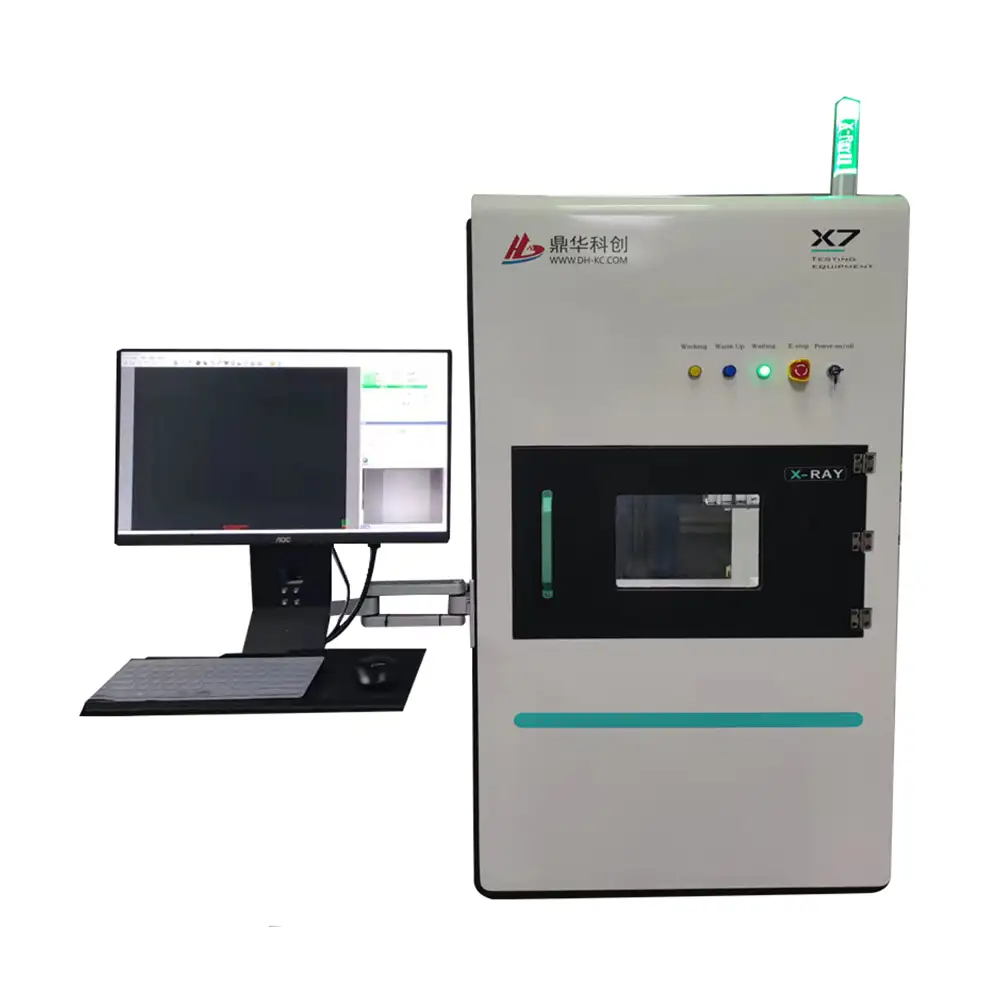

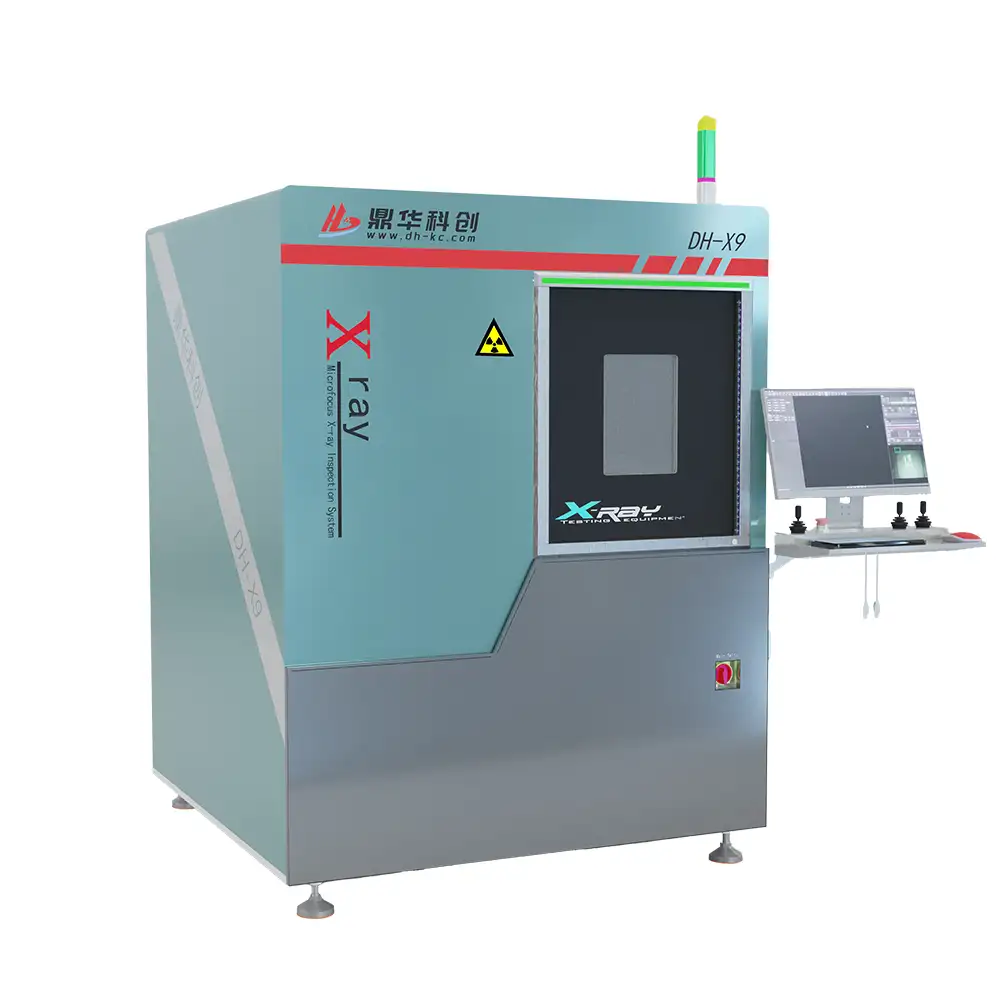

We are a leading manufacturer of BGA rework station, Xray inspection machine, Xray counter machine and automation equipment etc

Where is your factory?

We are located at 4F 6B, Shengzuozhi Technology Park, Xinqiao, Bao’an, Shenzhen, Guangdong, China

Are there over-seas after-sales service centers?

BGA rework station, Xray inspection machine, Xray counter machine and automatic soldering station consist of modularized structures, which are simple to change. So, if machines have a problem, changing its relevant part. We don’t arrange after-sales engineers to always live overseas, but, if our customers need extra service, our engineers can go to on-site

Have you had experiences cooperating with cross-border enterprises by today?

Yes, we do. Such as, Google, Foxconn, Micron, Vestel, Huawei, Kinpo and BYD etc

Online Message