Radiation value less than 0.18 msv

Image detector can be tilted up to120º

HD digital flat plate detector

Brightly LED light

Visible navigation window

Professional Equipment Manufacturer

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

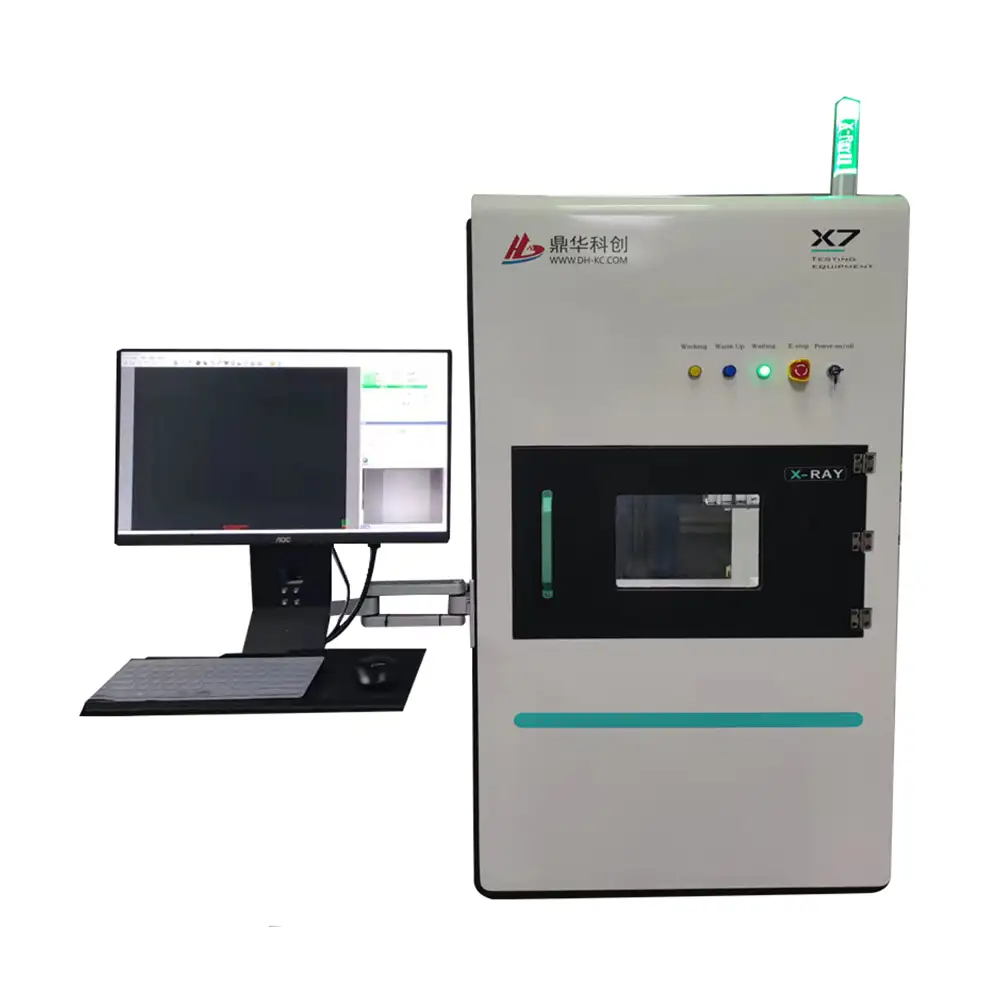

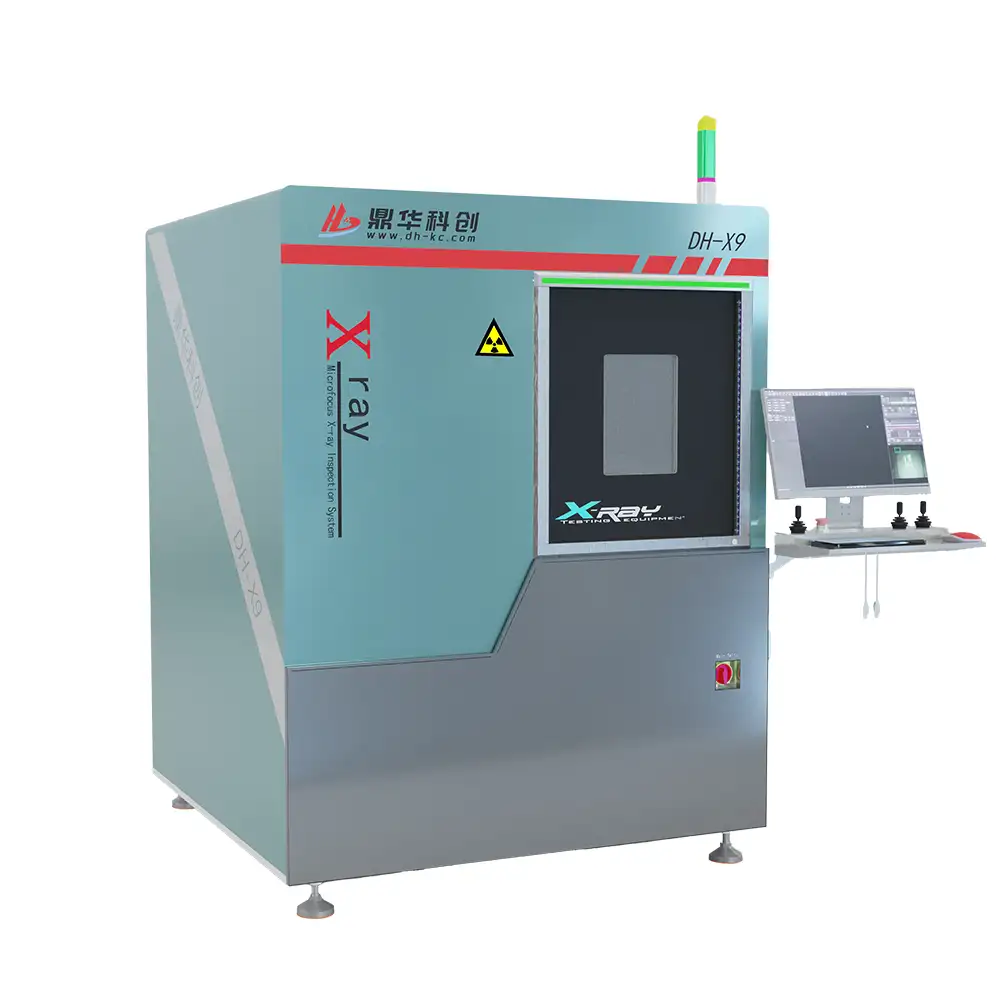

Xray inspection machine

Categories:

Keywords:

Product introduction

Product show

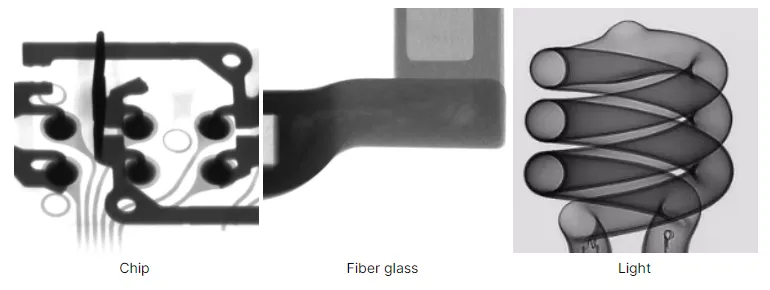

One of the key benefits of X-ray inspection machines is their ability to detect defects in products. This helps to improve the quality of products and prevent potentially dangerous items from reaching consumers. The use of X-ray machines in manufacturing has revolutionized the way products are made, ensuring that they meet the highest standards.

The machine equipped with laser position can be replaced quickly a chip on motherboard; 4 pcs thermocouples can help a technician test simultaneously 4 different positions temperature, make sure chip can be soldering well.

Radiation tested

X-ray inspection machines are highly effective tools used in the printed circuit board (PCB) industry. These machines play a crucial role in ensuring that the PCBs produced are of high quality and meet the required standards. X-ray inspection machines have several benefits, making them an essential asset to any PCB manufacturing facility.

Specification

X-ray inspection machines provide a non-destructive way of detecting any defects or faults in PCBs. The machines can detect internal issues that may not be visible to the naked eye, such as cracks, voids, and misalignments. This enables manufacturers to identify and correct any problems before the products are released to the market.

Product Specifications

No. | Item | Data | Item | Value |

1 | Power supply | 110V~240V +/-10% | Rated power | 1.7KW |

2 | Light tube type | sealed type | Light tube current | 200ɥA |

3 | Light tube voltage | 90KV | Geometry magnification | 200 times |

4 | Prober | New type TFT | Inspection mode | off-line |

5 | cooling-down method | Forced air cooling | Operate mode | Keyboard / mouse |

6 | Display | 24-inch HD monitor | Operating system | Windows10 64 |

7 | focal spot size | 5um | Door-opened | Manual+system induction |

8 | Spatial resolution | 14lp/mm | Authority management | password |

Product Configuration

Furthermore, X-ray inspection machines are capable of detecting defects in components such as ball grid arrays (BGAs) and surface mount technology (SMT) devices. These components have become increasingly popular in PCB manufacturing, and the ability to detect defects in them is critical in ensuring that the final product is of high quality.

Application cases

X-ray inspection machines are also highly accurate, reliable, and efficient. They can scan multiple PCBs simultaneously, enabling manufacturers to produce more products in less time. This saves time and resources while maintaining the highest quality standards.

Similar products

X-ray inspection machines are essential tools in the PCB manufacturing industry. They provide a non-destructive way of detecting defects, are highly accurate and efficient, and are capable of detecting internal issues in components. With these machines, manufacturers can produce high-quality PCBs that meet the required standards.

FACTORY WORKSHOP

CUSTOMER TRANSACTION

Adhering to the business principle of mutual benefits, we have had a reliable reputation among our customers because of our professional services, quality products and competitive prices.

CUSTOMER TRANSACTION

We welcome customers at home and abroad to visit our factory to reach long-term cooperation and create success together.

FAQ

Can you make a proof for using automatic soldering station:

Yes, please send us your motherboards and components,we can even customize a jig/fixture which will hold your motherboard & components on Machine’s table for soldering.

What is a BGA reworkstation?

Dinghua BGA rework stations, featured with 3 independent heating-area, PID controlling temperatures, real-time curves displaying on touchscreen, is a station used for various chips and a few components desoldering or soldering.

Are you a manufacturer or a trading company?

We are a leading manufacturer of BGA rework station, Xray inspection machine, Xray counter machine and automation equipment etc

Where is your factory?

We are located at 4F 6B, Shengzuozhi Technology Park, Xinqiao, Bao’an, Shenzhen, Guangdong, China

Are there over-seas after-sales service centers?

BGA rework station, Xray inspection machine, Xray counter machine and automatic soldering station consist of modularized structures, which are simple to change. So, if machines have a problem, changing its relevant part. We don’t arrange after-sales engineers to always live overseas, but, if our customers need extra service, our engineers can go to on-site

Have you had experiences cooperating with cross-border enterprises by today?

Yes, we do. Such as, Google, Foxconn, Micron, Vestel, Huawei, Kinpo and BYD etc

Online Message