Professional Equipment Manufacturer

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Oven

Categories:

Keywords:

Product introduction

1. Scope of use

This product is widely used in industrial and agricultural production, scientific research, PCB board drying, medical and health and other unit laboratories for drying, heat treatment and heating of test samples, but it is not suitable for volatile, flammable and explosive items to avoid Cause an explosion.

2. Principle and structure

The lower part of the working room of this product is equipped with a heating wire, and the left side is equipped with a blowing device. The temperature controller controls the constant high and low temperature. During operation, the air flows in from the air inlet at the bottom of the box, passes through the heating wire, and then flows into the working room through the blower device. Then it is discharged through the exhaust hole on the top of the box.

3. How to use

1. Before powering on, please make sure the switch is set to the "off" position and check for open circuit or leakage.

2. Since there will be a slight smoking process during the first heating, it is recommended not to put the sample before formal use, close the door, unscrew the exhaust cover on the top of the box, turn on the electric heating switch, the blower switch, and the indicator light will turn on. Set the heating switch to the "slow" position and set the temperature controller to 100°C. At this time, the temperature in the box begins to rise. When it reaches 100°C, the temperature controller automatically maintains the temperature. After that, the power can be cut off and the door of the box can be opened for cooling and cooling. Scatter the smoke.

3. For formal use, first place the sample on the shelf, close the door, unscrew the exhaust cover on the top of the box, connect the power supply, and turn on the electric heating switch and air blast switch. You can choose fast or slow heating during use. Then set the temperature controller to the required temperature. At this time, the temperature inside the box begins to heat up. When the temperature is constant, the heating gear should be set to the "slow" gear to ensure constant temperature fluctuation and uniform temperature inside the box.

4. Precautions

1. When using, the samples should not be placed too crowded to avoid affecting the convection in the box. When placing the box, please ensure that the box is effectively grounded to ensure safety. Do not touch the electrical circuit on the left side of the box with your hands or wet cloth when powering on;

2. When heating up, please do not splash water on the observation window of the box door to avoid the glass from being cold and prone to bursting;

3. This series of drying ovens are non-explosion-proof products;

4. Please do not put volatile, flammable and explosive items in the box for heating to prevent explosion.

5. Equipment model and parameters

Model | Volatage(V) | Power(KW) | Working temperaure() | Accuracy | Heating space(mm) | Dimension(mm) | Weight(kg) | ||||

101 | 220 | 1.6 | 50~300 | +/-1 | 350 | 450 | 450 | 500 | 810 | 810 | 70 |

102 | 220 | 2.4 | 50~300 | +/-1 | 450 | 550 | 550 | 600 | 910 | 910 | 100 |

103 | 220 | 3.0 | 50~300 | +/-1 | 500 | 600 | 750 | 650 | 960 | 1110 | 140 |

104 | 380 | 4.8 | 50~300 | +/-1 | 800 | 800 | 1000 | 1000 | 1210 | 1300 | 160 |

FACTORY WORKSHOP

CUSTOMER TRANSACTION

Adhering to the business principle of mutual benefits, we have had a reliable reputation among our customers because of our professional services, quality products and competitive prices.

CUSTOMER TRANSACTION

We welcome customers at home and abroad to visit our factory to reach long-term cooperation and create success together.

FAQ

Can you make a proof for using automatic soldering station:

Yes, please send us your motherboards and components,we can even customize a jig/fixture which will hold your motherboard & components on Machine’s table for soldering.

What is a BGA reworkstation?

Dinghua BGA rework stations, featured with 3 independent heating-area, PID controlling temperatures, real-time curves displaying on touchscreen, is a station used for various chips and a few components desoldering or soldering.

Are you a manufacturer or a trading company?

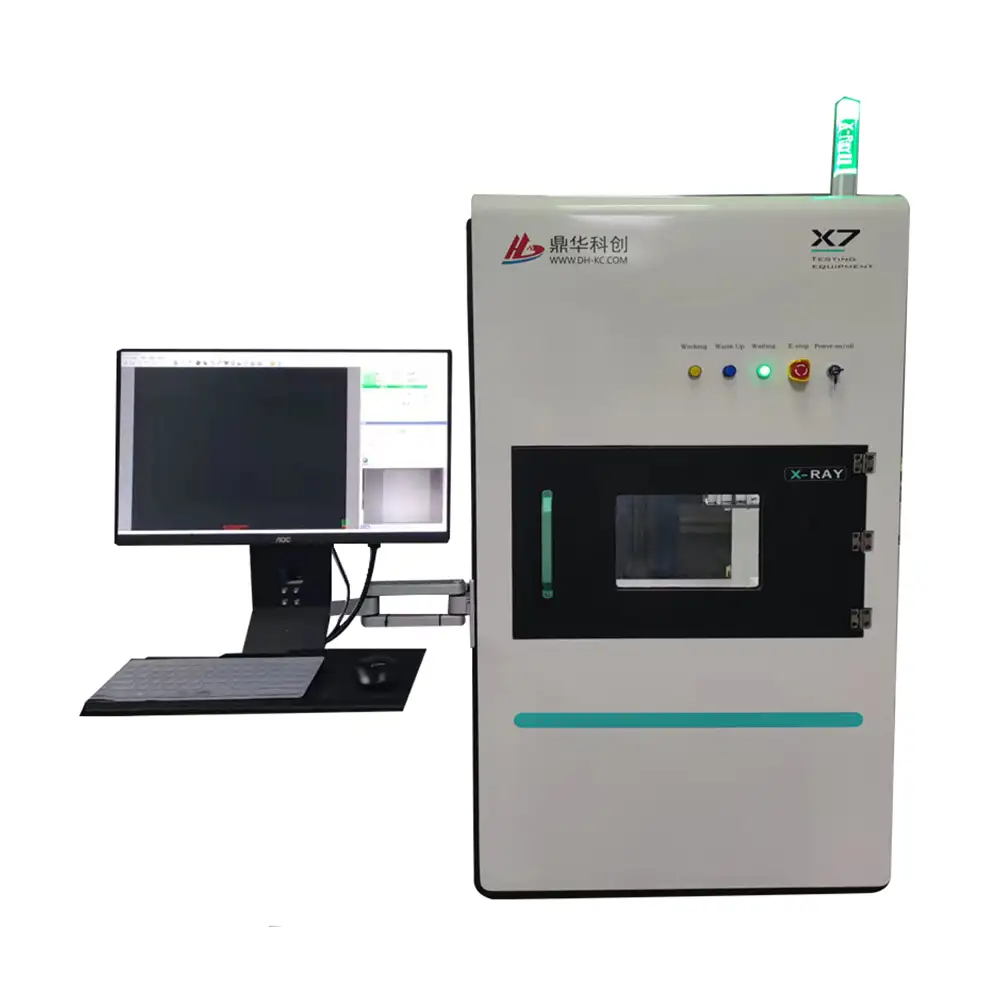

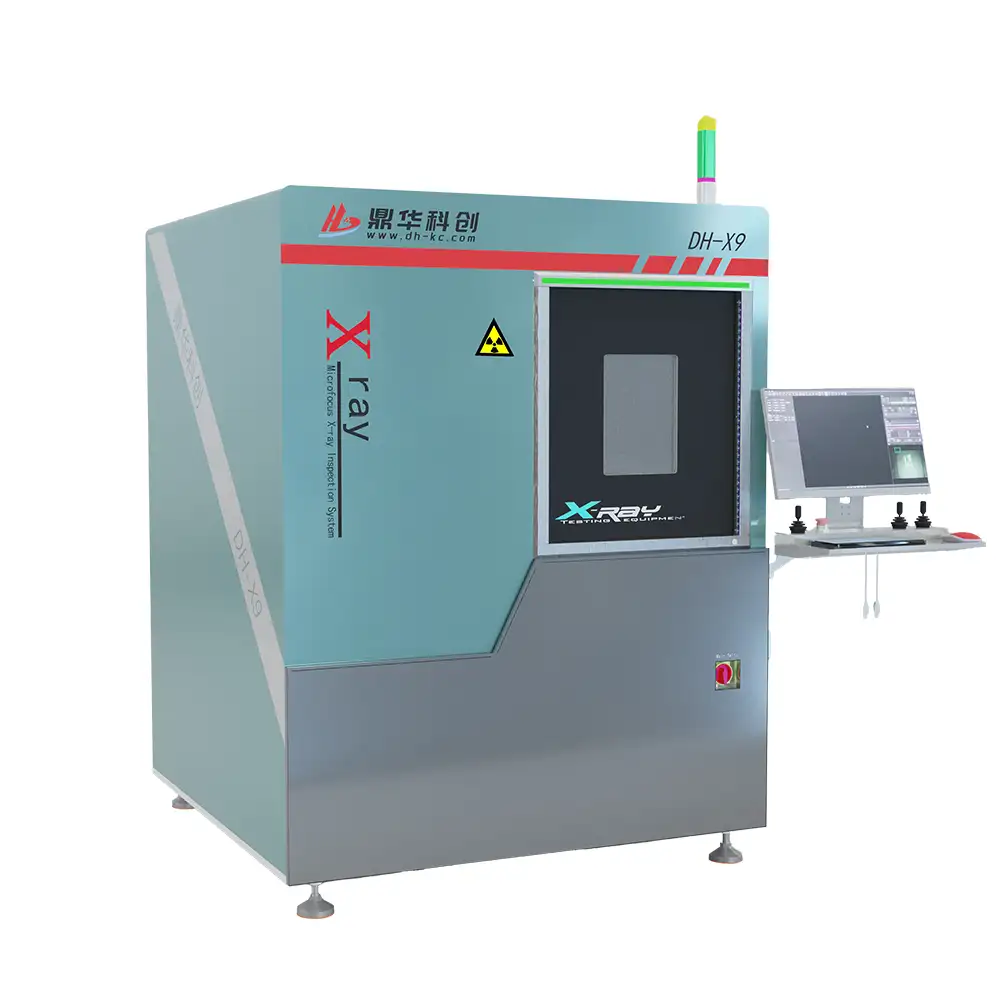

We are a leading manufacturer of BGA rework station, Xray inspection machine, Xray counter machine and automation equipment etc

Where is your factory?

We are located at 4F 6B, Shengzuozhi Technology Park, Xinqiao, Bao’an, Shenzhen, Guangdong, China

Are there over-seas after-sales service centers?

BGA rework station, Xray inspection machine, Xray counter machine and automatic soldering station consist of modularized structures, which are simple to change. So, if machines have a problem, changing its relevant part. We don’t arrange after-sales engineers to always live overseas, but, if our customers need extra service, our engineers can go to on-site

Have you had experiences cooperating with cross-border enterprises by today?

Yes, we do. Such as, Google, Foxconn, Micron, Vestel, Huawei, Kinpo and BYD etc

Online Message