Professional Equipment Manufacturer

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Furnace temperature tester

Categories:

Keywords:

Product introduction

This new and improved thermal profiler hardware is designed to withstand the roughest and toughest daily handling.

In addition, the electronic circuitry has been changed to tolerate the higher level voltage spikes that occasionally occur in some ovens and wave soldering machines. KIC offers customers real protection by backing this durable profiler with a standard two-year warranty.

The X5 TM thermal profiler is available in 7, 9 and 12 channel versions and uses standard K-type thermocouple connectors. Getting more data in a small unit is just the beginning. X5’s industry-leading performance Provides better data collection to accurately identify conditions for each thermal profile and process in the plant.

Hot profile data is conveniently transferred to your computer via USB connection. RF version of X5Real-time transmission of profile data to PC via wireless RF transmitter. Standard AAA battery

To power the X5, you have the option of using a rechargeable battery if you wish. X5 is connecting to compute.

The machine is also powered via the USB cable, bypassing the battery and thus extending its usage time.

Data Intelligence Software

X5's thermal analysis software uses a modern graphical interface to quickly and intuitively guide you through your analysis tasks.

Measure all critical profile and process data including slope, peak temperature, time above liquid, and more. Additionally, the software measures the Process Window Index™ (PWI) statistic. PWI mathematically and objectively determines whether your profile "fits" within an established process window. A PWI less than 100 indicates a profile that meets the specifications.

The PWI is lower because your process is centered in the window. Therefore, the lower the PWI, the deeper the sweet spot of the process window is.

PWI also instantly shows where your process or oven needs to be adjusted. The manual prediction feature is standard on the x5, allowing you to instantly see expected changes in contours and changes in oven setpoints. X5 Dual Mode includes passive analysis and recording capabilities as well as active oven setup and process optimization capabilities. Navigator Powerm software capabilities automate process improvements and equipment/machineization for you and come standard with the X5. In a few seconds Navigation Power will determine the single best oven setting based on the 3 optimization criteria of your choice.

X5's thermal analysis software uses a modern graphical interface to quickly and intuitively guide you through your analysis tasks.

Measure all critical profile and process data including slope, peak temperature, time above liquid, and more. Additionally, the software measures the Process Window Index™ (PWI) statistic. PWI mathematically and objectively determines whether your profile "fits" within an established process window.

A PWI less than 100 indicates a profile that meets the specifications.

The PWI is lower because your process is centered in the process window. Therefore, the lower the PWI, the deeper the sweet spot of the process window is.

PWI also instantly shows where your process or oven needs to be adjusted. The manual prediction feature is standard on the x5, allowing you to instantly see expected changes in contours and changes in oven setpoints.

change. X5 Dual Mode includes passive analysis and recording capabilities as well as active oven setup and process optimization capabilities. Navigator Powerm software capabilities automate process improvements and equipment/machine optimization for you and come standard with the X5. In a few seconds, the navigation power will be based on the 3 optimization criteria you selected.

Accurately determine individual optimal oven settings.

| Accuracy | 土0.59C |

| Resolution | 0.1°C |

| Internal operating temperature | 0°C to85*C |

| Sampling rate | 0.002 to10 Readings/second |

| data points | 224,640 |

| Computer connection | USB2.0 (Standard A/Mini B) |

| Power requirements | (3) AAABattery |

Thermocouple Compatibility | |

| 7.9. 12 channel unit | K type, standard |

| temperature range | -150°C to 1050°C |

Dimensions (length x width x height) | |

| 7 channel unit | 202.0x 60.0x 17.0 |

| 9 channel unit | 202.0x 75.0x 17.0 |

| 12 channel unit | 208.0x 980x 17.0 |

Heat shield: Temperature seen Heat Shield: See below for specifications Temperature tolerance table | |

Accurately determine individual optimal oven settings.

Data Logger Model: Download data to computer via USB cable after run

Two-machine model: data is sent to the computer in real time during operation

Data is also stored internally for USB download after running

Note: Analysis software can interface directly with some oven controllers, eliminating the need to manually enter setpoint values.

Please check with your oven supplier for availability

Performance analysis software is protected by an add-on dog.

Accuracy based on factory calibration

Configuration | Dimensions (mm)(LxWxH) | 150°C | 200°C | 250°C | 300°C | 350 | 400°C |

Anti-scalding stainless steel insulation cover, 7 channels | 302x 75x 23 | 17.5 | 12 | 9 | 7.7 | 6.5 |

|

Anti-scalding stainless steel insulation cover 9 channels | 312x90 x23 | 18.1 | 13.1 | 10.1 | 8.4 | 6.7 |

|

Anti-scalding stainless steel insulation cover 12 channels | 323x 113x23 | 17.7 | 12 | 8.9 | 7.4 | 6.1 |

|

HT Shield 400 | 298x 106x 29 | 24.9 | 17.6 | 14 | 11.5 | 10.1 | 9.2 |

X5 complete set of products includes:

Tester :Suitcase

Insulation sleeve:thermocouple

Software CD :User manual electronic file

Software Protection Lock:Gloves

USB connection transmission cable:user guide

AAA battery:inspection certificate

Scissors:USB metal connection extension cable

Wireless transmission terminal:(receiver/transmitter)

Minimum computer configuration requirements

Dual core/1Ghz processor/2Gb RAM

2G hard disk space

1024x 768 monitor

2 USB ports (1Key-1Data)

Microsoft Windows XP/Vista/7 (32/64bi)

FACTORY WORKSHOP

CUSTOMER TRANSACTION

Adhering to the business principle of mutual benefits, we have had a reliable reputation among our customers because of our professional services, quality products and competitive prices.

CUSTOMER TRANSACTION

We welcome customers at home and abroad to visit our factory to reach long-term cooperation and create success together.

FAQ

Can you make a proof for using automatic soldering station:

Yes, please send us your motherboards and components,we can even customize a jig/fixture which will hold your motherboard & components on Machine’s table for soldering.

What is a BGA reworkstation?

Dinghua BGA rework stations, featured with 3 independent heating-area, PID controlling temperatures, real-time curves displaying on touchscreen, is a station used for various chips and a few components desoldering or soldering.

Are you a manufacturer or a trading company?

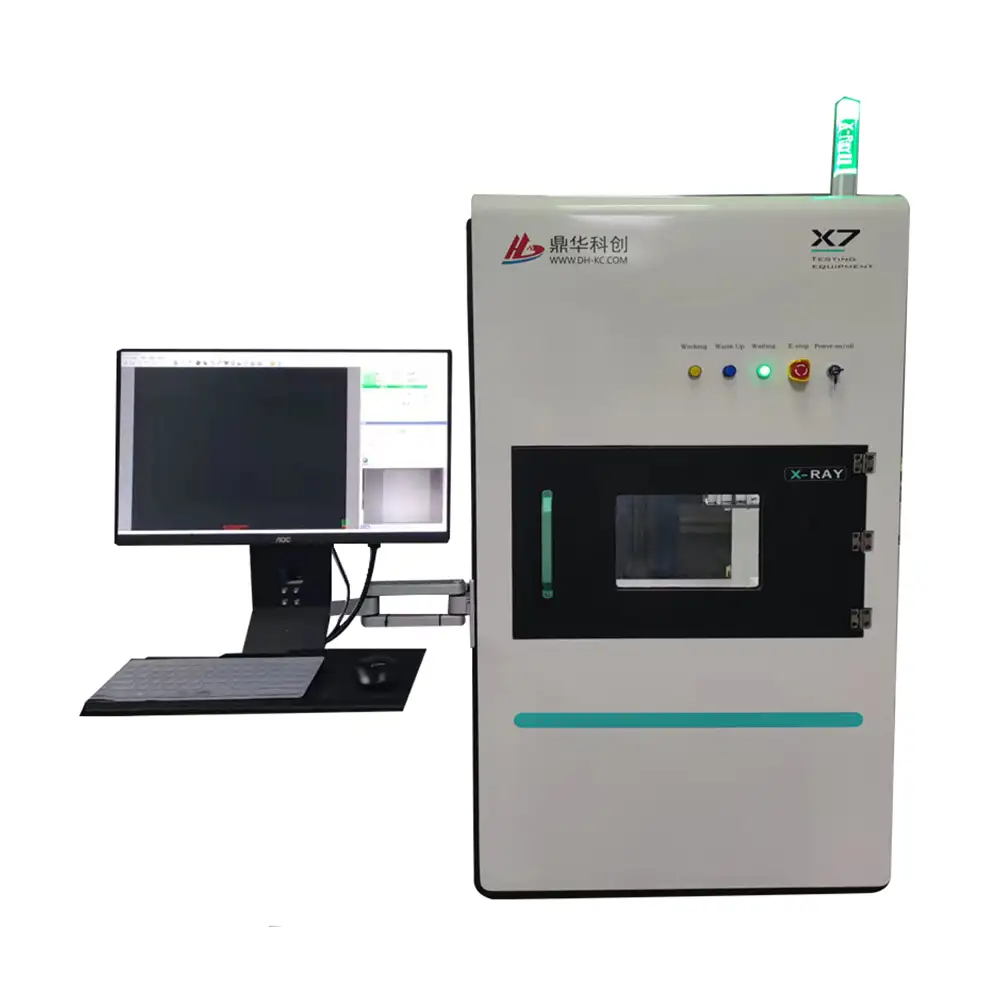

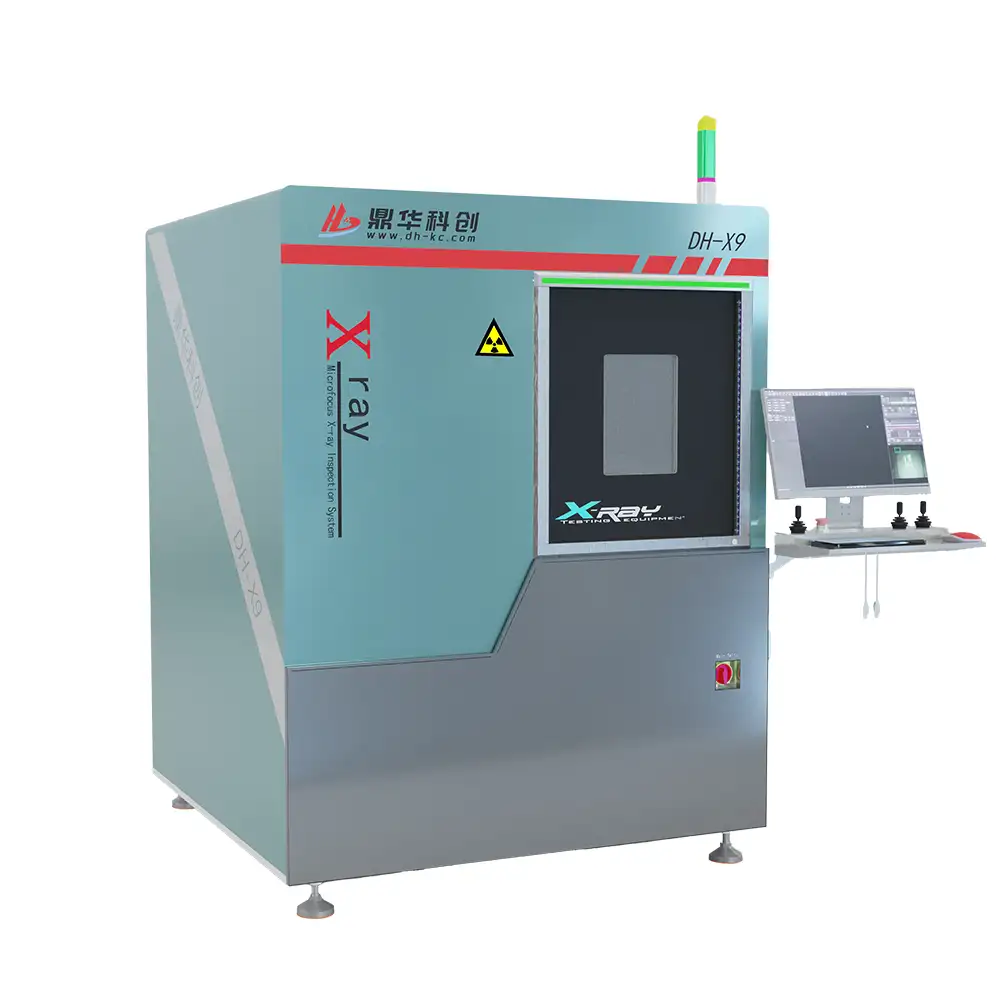

We are a leading manufacturer of BGA rework station, Xray inspection machine, Xray counter machine and automation equipment etc

Where is your factory?

We are located at 4F 6B, Shengzuozhi Technology Park, Xinqiao, Bao’an, Shenzhen, Guangdong, China

Are there over-seas after-sales service centers?

BGA rework station, Xray inspection machine, Xray counter machine and automatic soldering station consist of modularized structures, which are simple to change. So, if machines have a problem, changing its relevant part. We don’t arrange after-sales engineers to always live overseas, but, if our customers need extra service, our engineers can go to on-site

Have you had experiences cooperating with cross-border enterprises by today?

Yes, we do. Such as, Google, Foxconn, Micron, Vestel, Huawei, Kinpo and BYD etc

Online Message